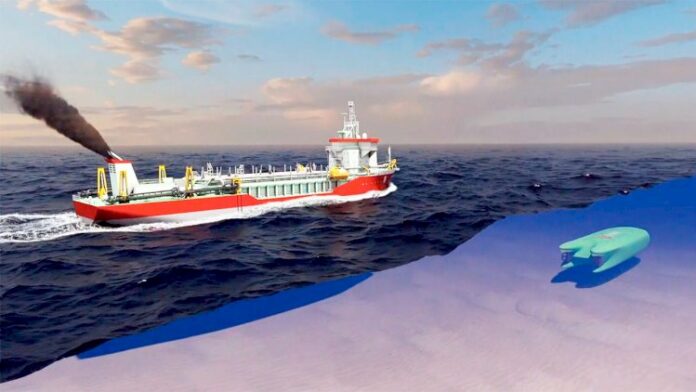

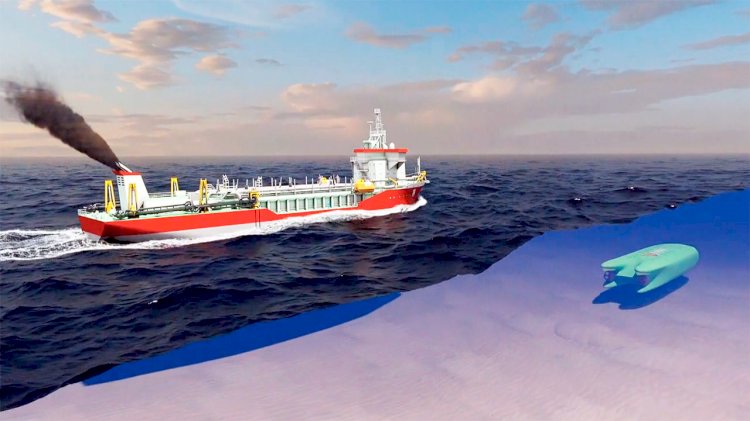

C-Job Naval Architects has revealed its concept design of an Autonomous Underwater Maintenance Dredger. The unique design was presented by the independent ship design and engineering company at the combined Maritime and Port Technology and Development Conference (MTEC) and international Conference on Maritime Autonomous Surface Ships (ICMASS) in Trondheim, Norway.

The Autonomous Underwater Maintenance Dredger (AUMD) concept design developed by C-Job’s Research and Development department is specifically created for maintenance in port environments. The team took advantage of the opportunities and out-of-the-box solutions autonomous vessels provide such as completely submerging a dredging vessel.

This one-of-a-kind design is sustainable as it requires significantly less power compared to a conventional dredger which enables a 16MWh battery pack to power the AUMD and provides maintenance dredging for up to 12 hours.

Rolph Hijdra, Autonomous Vessels Research Lead at C-Job, says:

“When we developed this exciting design, we performed a comparison study with a conventional Trailing Suction Hopper Dredger. This showed that the Autonomous Underwater Maintenance Dredger requires 55% less propulsion power and by submersing the vessel we could reduce the suction head cutting the dredge pump power demand by 80%.”

The submersion of the design also increases operability as it mitigates wave motions as she’s capable to remain submerged throughout the dredging cycle. She only needs to surface for repair, maintenance and charging her batteries. The AUMD features the same hopper volume as the traditional dredger even though the overall length of C-Job’s design has been reduced by 20%.

Rolph continues:

“Autonomous shipping provides enormous potential for ship owners, with both technical design and economic benefits. According to our research, even with a conservative approach, we found that with the AUMD ship owners can expect nearly twice as much profit after 15 years. Though there’s a higher initial investment, operational cost are much lower which makes it an interesting option for companies to consider.”

While the Research and Development team focused on reduced power demand, sustainability, and operability, they also considered other aspects of the design. This includes emergency access which can be obtained through the diver’s lock included in the design. Data communication with the vessel was envisaged via shore-based communication networks such as 4G/5G.

Tim Vlaar, Technical Director at C-Job, says:

“In order for autonomous vessels like the Autonomous Underwater Maintenance Dredger to become reality more work is needed and requires all stakeholders such as class, port authorities, Autonomous Technology companies and launching customers to come together. Of course, continued development of autonomous vessel designs is also needed to fully explore the possibilities autonomous shipping presents even further.”

C-Job is renowned for its innovative ship design and engineering and has a strong track-record in several industries including Dredging, Offshore (Wind), Ferries, Yachts and Workboats. The company has a dedicated Research and Development department which focuses on new ways to improve and be innovative with both its designs as well as in the creation of these designs. This allows the company to show the economical and operational consequences in each design. Recent projects include the Autonomous Underwater Maintenance Dredger and exploring NH3 as a marine fuel.