The Western Australian Minister for Ports, the Hon. Alannah MacTiernan MLC has opened the expanded facilities of HR Wallingford’s state-of-the-art Australia Ship Simulation Centre.

HR Wallingford has added two new purpose-built simulators to its world-leading centre in Fremantle, bringing the total number of simulators that it owns and operates there to six. This makes it one of the largest ship simulation centres in Australia and allows a full manoeuvring team (including pilots, tug masters and vessel traffic service (VTS) operators) to conduct integrated and immersive full port scenarios.

The Minister said:

“I am delighted that HR Wallingford has invested in this centre, further helping to ensure the smooth running and safety of our ports. Specialist leading-edge facilities such as these are essential to ensure our ports and terminals are designed and operated to the highest of standards.”

The largest new simulator has an impressively wide beam of over 8m and would typically be configured as a ship’s bridge, while four of the other simulators would typically represent tugs. That said, the system is extremely flexible and all simulators can be easily configured to simulate any type of vessel, as required. The sixth simulator is primarily intended to be set up as a VTS (similar to air traffic control for ports), but can also function as a secondary ship or tug bridge.

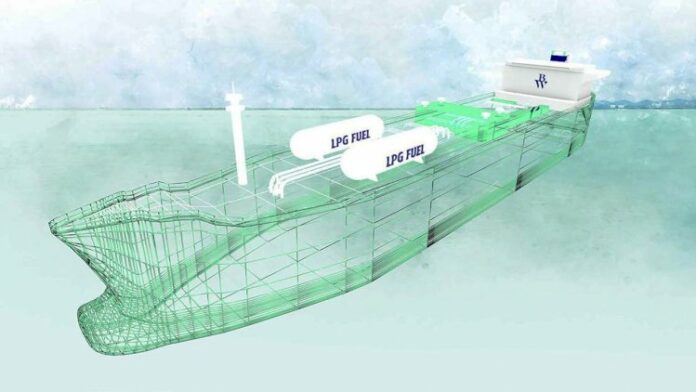

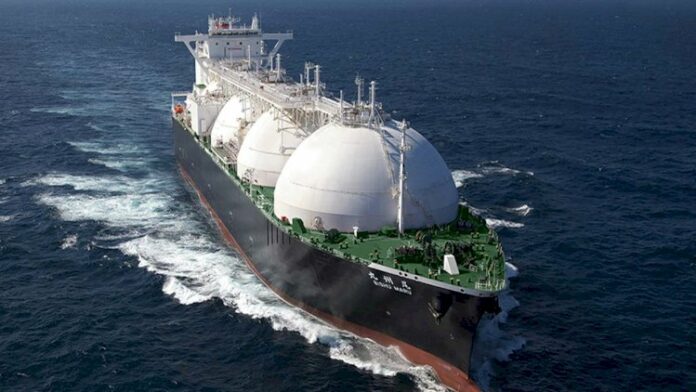

By building in flexibility in the configuration and operation of its simulators, the centre can meet a wide range of customer requirements. All of the simulators can be linked together to represent a single virtual port environment or run separately to allow for a number of scenarios at one time. HR Wallingford has extensively used one or more of its simulators for comprehensive port design work in Australia, for example for Chevron Australia’s Gorgon and Wheatstone LNG Terminals and Shell Australia’s Prelude FLNG. The linked simulators are also ideal for mariners to familiarise themselves with new port layouts, larger or new classes of ships, and to allow marine pilots and tug masters to practice specialist manoeuvres together.

HR Wallingford’s decision to expand the facility was prompted in part by a new four-year contract recently signed with the Pilbara Ports Authority (PPA) to provide integrated pilot and tug master training. PPA, which operates Port Hedland, the world’s largest bulk export port, has been carrying out training at the centre for the last six years.

Capt John Finch, General Manager of Operations at the PPA, said:

“We are really impressed with the expanded facilities – they are ideally suited for our needs and have improved the realism for our marine pilots and tug masters. Safety is of paramount importance to us, so it is essential for the full port resource management team to be able to train together for particular situations, including emergency responses.”

Over the last eight years, HR Wallingford’s Australia Ship Simulation Centre has served many high-profile customers, including all of Australia’s major LNG terminals, many bulk liquid companies and the west coast’s largest mining companies.

HR Wallingford’s Ships and Dredging Group Manager, Dr Mark McBride, commented:

“We are extremely proud of our UK and Australia Ship Simulation Centres, which draw on our 30+ years of experience in developing bespoke hardware and software. By building the systems ourselves, we can ensure they are sufficiently flexible to allow efficient modifications and updates to reflect any changes in port layouts or ships. We are also able to adapt scenarios quickly to meet particular port design and training needs.”