Known as air lubrication, the technology is one of the solutions being tested by the company to achieve its climate goals.

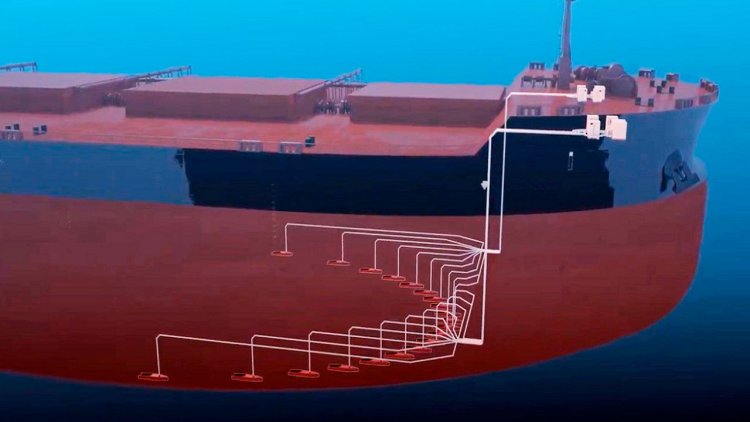

Air bubbles, produced artificially under the ship’s hull, will help Vale further reduce its greenhouse gas (GHG) emissions from navigation. The technology, known as air lubrication, was installed in the Sea Victoria, a Guaibamax with a capacity of 325 thousand tons. Ten compressors installed on the ship’s deck send air to twenty devices positioned under the ship to produce a carpet of bubbles. These bubbles reduce the friction between the hull and the water, reducing fuel consumption and, consequently, emissions. Sea Victoria, which is already on its way to Brazil, is the first ore carrier in the world to use this technology.

Vale’s navigation team estimates that, if the test is successful, the technology could be replicated on the remainder of the contracted fleet dedicated to transporting the company’s ore.

Rodrigo Bermelho, Technical Manager – Navigation, Vale, explains:

“Conservative estimates point to a fuel reduction of around 5 to 8%, with a potential reduction of 4.4% in annual emissions from Vale´s maritime transport of iron ore.”

The technology is supplied by the English manufacturer Silverstream. Vale developed the project in partnerships with ITV (Vale Institute of Technology) and the Korean shipowner Pan Ocean to install the technology on one of the VLOCs (Very Large Ore Carrier) dedicated to transport Vale ores. Shanghai Ship Design Research Institute (SDARI) was responsible for the ship design and its integration with the bubbles. The Chinese shipyard, New Times Shipbuilding, prepared the vessel during its construction and the shipyard, Yiu Lian Dockyards (Shekou) LTD, located in the Chinese city of Shenzhen, installed the equipment. The installation took 35 days and the ship was ready on the June 28th.

The adoption of air lubrication is part of Vale´s Ecoshipping program, a program created to meet the challenge of reducing the company’s carbon emissions, in line with what has been discussed within the scope of the International Maritime Organization (IMO). Last year, the company announced that it intends to neutralize its direct and indirect emissions (scopes 1 and 2) in 2050 and still reduce scope 3 emissions by 15% by 2035. Scope 3 emissions are emissions from the company’s value chain, which includes emissions from shipping since the company contracts the ships from third parties to transport their ore. Vale’s emission reduction goals are in line with the ambition of the Paris Agreement.

Noah Silberschmidt, Founder & CEO, Silverstream Technologies, says:

“The Silverstream® System will drive a step change in fuel and emissions efficiency on the Sea Victoria and prove what is possible on their dry bulk vessels. For the industry at large, we are also proving that there are actions that we can take today to mitigate the environmental impact of our operations.”

Rodrigo Bermelho, Technical Manager – Navigation, Vale, says:

“Vale transports iron ore in the most efficient vessels in the world, but we believe there are still further energy efficiency gains to be captured to reduce fuel consumption and CO2 emissions. This pioneering project shows our commitment to supporting the shipping industry in fulfilling the ambitions of the International Maritime Organization (IMO).”