Norway's prime minister Erna Solberg will perform the official opening of the Johan Sverdrup field centre today, and the Minister of Petroleum and Energy, Sylvi Listhaug, will also attend the opening.

Since Equinor and the Johan Sverdrup partners Lundin Norway, Petoro, Aker BP and Total started the field on 5 October last year, production has increased to a level well above 300,000 barrels per day.

Johan Sverdrup is expected to yield a total production revenue exceeding NOK 1 400 billion and more than NOK 900 billion in revenue to the Norwegian state.

Expected recoverable Johan Sverdrup reserves are 2.7 billion barrels of oil equivalent. Two thirds of the oil from Johan Sverdrup are expected to be produced before 2030.

The field is setting a new standard for CO2 efficiency. Land-based power supply leads to record-low CO2 emissions of well below 1kg per barrel, compared to a global average of around 18kg.

Eldar Sætre, CEO of Equinor, says:

“Johan Sverdrup offers both high value creation and record-low emissions, making Johan Sverdrup a future-oriented oil field and part of the solution for reduced emissions. Electrification is an important tool for reaching Norwegian and international climate goals, aiming to reduce our greenhouse gas emissions in Norway by 40% by 2030, and close to zero emissions in 2050.”

Johan Sverdrup is based on a long history of valuable experience and expertise. The field is also a pioneer in using technology and digitalization.

Arne Sigve Nylund, executive vice president for Development and Production Norway, says:

“Digitalization offers new opportunities that few people deemed possible only a few years ago. It is necessary to secure the transformation we need to succeed in our future industrial activities and value creation on the Norwegian continental shelf.”

Digital solutions are integrated on the field – as an example we are monitoring the reservoir and optimizing production thanks to huge amounts of data transmitted from the wells. A “digital twin” provides a virtual real-time version of what is happening on Johan Sverdrup. This analytical tool helps improve safety, increase revenue and reduce emissions.

The field is expected to produce up to 660,000 barrels of oil per day in full production. Plateau production for phase 1 is up to 440,000 barrels of oil per day and is expected to be reached in the summer of 2020.

Nylund says:

“We are working systematically on creating higher value from the field and achieving an optimal recovery rate. The field ambition is to reach a recovery rate above 70%.”

In the operating phase Johan Sverdrup may also create jobs corresponding to an average of more than 3 400 man-years per year.

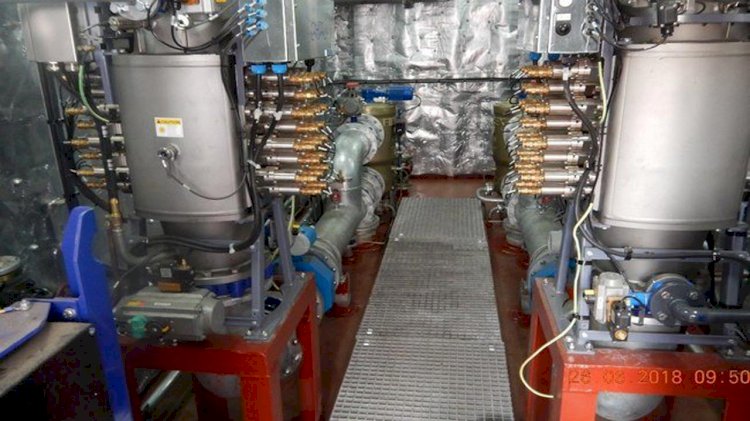

Removing unwanted organisms from seawater is a complex and costly process for a shipowner. The industry needs to implement regulations that will be immediately effective, and continue to be so well into the future. Discussions on how best to achieve this have been ongoing for years, but an agreement on mutually approved solutions has, so far, proved elusive.

Removing unwanted organisms from seawater is a complex and costly process for a shipowner. The industry needs to implement regulations that will be immediately effective, and continue to be so well into the future. Discussions on how best to achieve this have been ongoing for years, but an agreement on mutually approved solutions has, so far, proved elusive.