Aker Solutions has been awarded a contract from Aker BP to deliver the subsea production system for the second phase of the Ærfugl development offshore Norway.

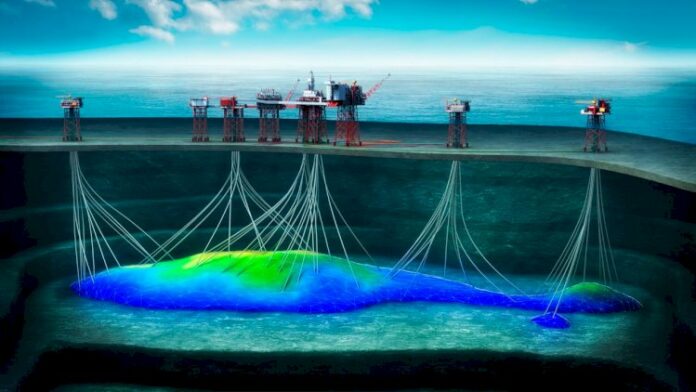

The subsea delivery will include wellheads, vertical subsea trees, satellite structures, control systems, a tie-in module and about 30 kilometers of umbilicals. The contract has a value of about NOK 700 million, which will be booked as order intake in the fourth quarter.

Egil Bøyum, executive vice president, greenfield projects, at Aker Solutions, said:

"The subsea alliance between Aker Solutions, Subsea 7 and Aker BP has already demonstrated great value through a series of subsea project deliveries. Close cooperation between the parties is instrumental in making both phase one and two of the Ærfugl project a success."

Bøyum adds:

"Our deliveries to Ærfugl highlight the power of Intelligent Subsea, as we utilize our integrated field design capabilities to accelerate the field development and maximize performance."

The deliveries include the Vectus™ next generation subsea control system, which offers greater data and power capabilities, and Aker Solutions’ standard, lightweight vertical subsea trees.

The work starts immediately and involves facilities in Norway, the UK, India, Malaysia and Brazil. The subsea structures are scheduled for delivery in 2020. Ærfugl is a gas condensate field about 210 kilometers offshore Sandnessjøen in Norway. It is connected back to the Skarv floating production, storage and offloading (FPSO) vessel operated by Aker BP. The field design has been optimized with respect to both subsea architecture and corresponding infrastructure, such as the FPSO topside and SURF (Subsea Umbilicals, Risers and Flowlines). The field design also includes capacity to accommodate future tiebacks in the area.

Aker Solutions delivered the subsea production system for the first phase of the Ærfugl development, as part of the company’s subsea alliance with Aker BP and Subsea 7. Intelligent Subsea is Aker Solutions’ approach to addressing the current and future needs of subsea production through integrated field design, accelerated development and maximized performance. This approach can cut the cost of field development capex by as much as 50 percent and reduce engineering hours during development by even more.

The National Geographic Endurance is the first of two vessels of the CX104 design from Ulstein for construction at Ulstein Verft, Norway. The yard is situated at 62 degrees north, just four degrees south of the Polar Circle, and at the edge of one of the world’s toughest oceans, the North Sea.

The National Geographic Endurance is the first of two vessels of the CX104 design from Ulstein for construction at Ulstein Verft, Norway. The yard is situated at 62 degrees north, just four degrees south of the Polar Circle, and at the edge of one of the world’s toughest oceans, the North Sea. That’s one of the reasons why the vessel has been named after the polar hero, Ernest Shackleton’s, favourite vessel, the Endurance. The Endurance and her crew endured the toughest of polar expeditions. The modern, next-generation, National Geographic Endurance, is purpose-built for polar navigation and will provide far more comfort for those onboard.

That’s one of the reasons why the vessel has been named after the polar hero, Ernest Shackleton’s, favourite vessel, the Endurance. The Endurance and her crew endured the toughest of polar expeditions. The modern, next-generation, National Geographic Endurance, is purpose-built for polar navigation and will provide far more comfort for those onboard. A fully stabilized, highly strengthened, ice-class Polar Code Category A vessel, she is designed to navigate polar passages year-round, and safely explore unchartered waters, while providing exceptional comfort. She carries a full suite of expedition tools and offers a variety of experience-enhancing amenities. The ship’s expanded fuel and water tanks provide for extended operations in remote areas.

A fully stabilized, highly strengthened, ice-class Polar Code Category A vessel, she is designed to navigate polar passages year-round, and safely explore unchartered waters, while providing exceptional comfort. She carries a full suite of expedition tools and offers a variety of experience-enhancing amenities. The ship’s expanded fuel and water tanks provide for extended operations in remote areas.  The National Geographic Endurance comfortably accommodates 126 guests in 69 outside-facing cabins. Most cabins will feature small balconies with floor-to-ceiling sliding doors that bring in the spectacular views and ample natural light.

The National Geographic Endurance comfortably accommodates 126 guests in 69 outside-facing cabins. Most cabins will feature small balconies with floor-to-ceiling sliding doors that bring in the spectacular views and ample natural light.