The Ocean Cleanup has announced, at the UN Ocean Conference (UNOC), its plan to rapidly expand its work to intercept and remove ocean-bound plastic pollution.

The 30 Cities Program will scale the organization’s proven Interceptor™ solutions across 30 key cities in Asia and the Americas, aiming to eliminate up to one third of all plastic flowing from the world’s rivers into the ocean before the end of the decade.

This evolution follows five years of learning through pioneering deployments across 20 of the world’s most polluting rivers and represents a key next step in the organization’s mission and the global fight against ocean plastic pollution.

With the 30 Cities Program, The Ocean Cleanup will transition from single river deployments to citywide solutions, tackling the main plastic emitting waterways within each selected city. This follows a key learning from deployments in Kingston, Jamaica, which showed it is possible to scale faster when projects encompass whole cities, as the same set of partners can be involved with all deployments.

To date, The Ocean Cleanup has already prevented over 29 million kilograms of trash from reaching the ocean. The organization currently intercepts an estimated 1–3 percent of global river-borne plastic emissions. With the first 20 river deployments close to being fully operational, it is now poised to reduce the plastic pollution flowing into the ocean from rivers by up to a third.

“When we take on an entire city, instead of individual rivers, we can scale faster, reduce costs, and maximize impact,” said Boyan Slat, Founder and CEO of The Ocean Cleanup.

“Our analysis shows that strategically deploying Interceptors across just 30 carefully chosen cities can stop up to a third of river plastic pollution worldwide. This is the next big leap toward our ultimate goal of a 90 per cent reduction in global ocean plastic pollution.”

City-by-city: a faster path to scaling

Using the latest scientific modeling and on the ground experience, The Ocean Cleanup identified 30 major plastic polluting coastal cities which include:

- Panama City, Panama – First deployment to go live in the coming months.

- Mumbai, India – Mapping of all waterways completed; preparations for first deployments underway.

Furthermore, the organization is developing plans to expand on its existing work to all polluting rivers in:

- Manila, Philippines; Montego Bay, Jamaica; Jakarta, Indonesia; Kuala Lumpur, Malaysia; Bangkok, Thailand and Los Angeles, U.S.A.

Other cities will be announced once the necessary partnerships and agreements are in place. Planning and fundraising activities are underway for all 30 cities. To realize these ambitious plans, the organization is currently also expanding its engineering and operational capacity.

Data Driven Restoration at Scale

Before Interceptors are deployed, each city project begins with an intensive analysis phase. Aerial drones, AI-powered image analysis, and GPS-tagged “dummy” plastics are used to chart every visible waterway and track how waste moves from streets to sea. These real-time insights guide optimal Interceptor placement and provide a public baseline against which progress can be measured.

Alongside intercepting new plastic, the 30 Cities Program will also remove debris from nearby coasts, mangroves, and coral reefs. This twin-track approach—shutting off the tap while clearing the legacy pollution—enables The Ocean Cleanup to achieve long-term impact, which includes the restoration of fish nursery habitats, boosting coastal tourism, and strengthening of natural storm surge defenses for local communities. Alongside local partners, the organization also advocates for improvements in waste management and awareness raising amongst communities.

Completing the first 20 Rivers

While laying the foundation for the 30 Cities Program, The Ocean Cleanup is also nearing completion of its first 20 river projects. The next landmark achievement—expected as soon as the second half of this year—is in the western Caribbean, where the team aims to resolve the plastic pollution problem in the Gulf of Honduras by intercepting the trash feeding into this body of water.

A Stepping Stone Toward a 90 Percent Reduction

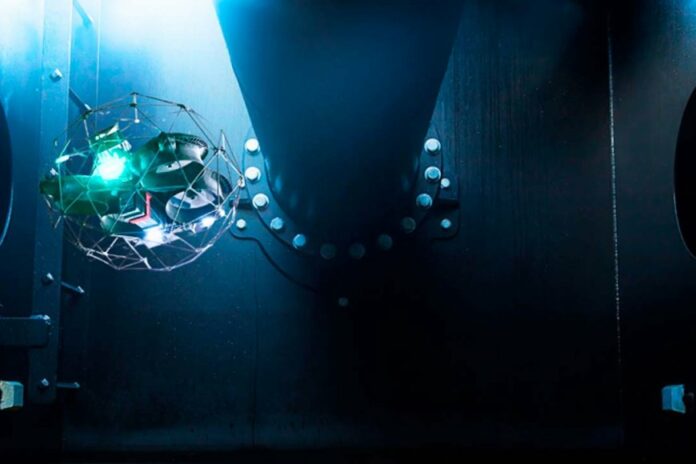

The 30 Cities Program represents the first major scaling step in The Ocean Cleanup’s journey to eliminate 90 percent of floating ocean plastic pollution. In parallel, efforts are continuing to remove plastic from the Great Pacific Garbage Patch. Whilst extraction operations are currently on hiatus, work to deploy cutting edge technologies to map the “hotspots”, or areas of intense plastic accumulation, in order to make future extractions more efficient and economical, is ongoing.

By combining river interception and coastal cleanup with its offshore cleanup systems targeting legacy pollution that’s already in the ocean, the organization is charting a path to turn off the tap and mop up the mess.