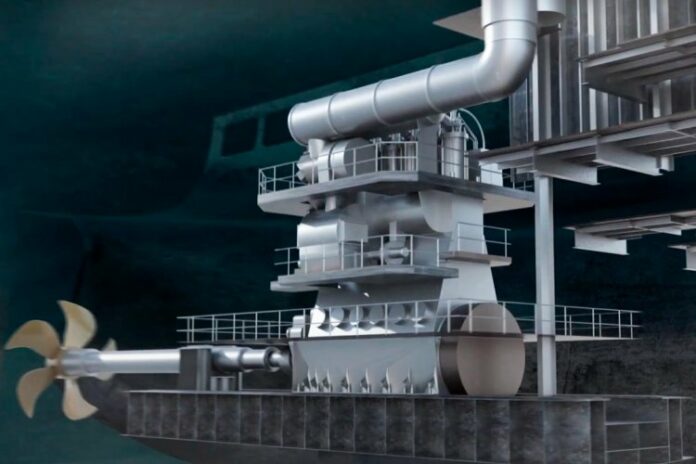

A trial of the 65-meter tug, controlled from a remote location at the Maritime and Port Authority of Singapore’s Maritime Innovation Lab, was successfully performed in April 2021.

The second phase of the project, scheduled for late 2021, will see the vessel perform autonomous collision avoidance tasks while under remote supervision. The Maju 510 tug is owned and operated by Keppel O&M’s joint-venture company Keppel Smit Towage.

The project was one of a series of industry-leading initiatives to inform the development of the recently published ABS Guide for Autonomous and Remote-Control Functions, which introduced the REMOTE-CON notation and another recognizing autonomous functions. The Guide sets out a goal-based framework for the implementation of these technologies on vessels and offshore units.

Patrick Ryan, ABS Senior Vice President, Global Engineering and Technology, said:

“This landmark project demonstrates the rapid advance of remote control and autonomous technology at sea. This vessel is the first to receive the REMOTE-CON (NAV, OP1) notation and is blazing a trail others are sure to follow. ABS is involved in cutting-edge projects all over the world designed to advance the application of remote and autonomous functions on vessels and we are proud to play a role in supporting the safe development of this technology at sea.”

Mr. Tan Leong Peng, Managing Director (New Builds), Keppel O&M, said:

“As the overall system integrator, Keppel O&M is able to provide technology solutions and integrate best-in-class systems to offer customizable remote and autonomous function for vessels. With the offshore and marine sector evolving rapidly, we are leveraging our engineering expertise and harnessing advanced technologies to stay at the forefront of the industry. In line with Keppel’s Vision 2030, we are also collaborating with the Keppel ecosystem of companies, such as M1 with its connectivity solutions, to enhance our value add.”

Mr. Romi Kaushal, Managing Director of Keppel Smit Towage, said:

“Keppel Smit Towage is pleased to receive the world’s first ABS Remote-Control Navigation Notation. It is a testament to our commitment to continuously harness technology and improve safety of operations to serve customers better. Remote and autonomous functions can significantly enhance safety and efficiency of tug operations by automating simpler tasks, allowing the crew to focus on more technical or crucial matters.”