Equinor, operator of the world’s first floating offshore wind farm, Hywind Scotland, has pioneered a novel method of data collection for offshore wind, using an autonomous Sailbuoy.

Powered by the wind and sun, the glider travelled on its own from Bergen, Norway, to the wind farm just off the coast of Peterhead, Scotland, where it used acoustic sensors to map fish presence and biomass quantity.

The Sailbuoy, operated by Akvaplan-niva, is equipped with an echosounder to identify adult fish. Equinor hopes the results will provide further insight on interactions between floating offshore wind farms and marine life.

Beate Myking, SVP Renewable Solutions said:

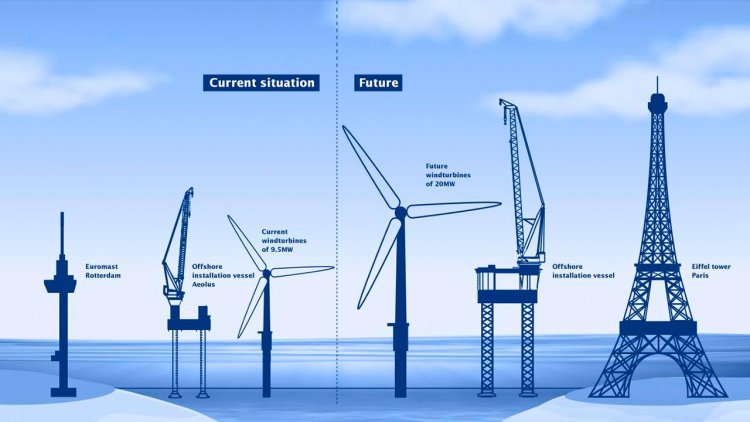

“Following the success of fixed-bottom offshore wind, the global industry is extremely excited about floating offshore wind as it opens up new markets with deeper coastlines, allowing countries to access homegrown renewable energy. As the developer with the most experience in floating offshore wind, we want to use Hywind Scotland as much as possible to undertake studies, learn and share information about how the substructures interact with marine life.

“There are several benefits from using an autonomous vehicle when mapping an area for fish biomass; safety risk for personnel is reduced to zero, no CO2 emissions, it’s extremely cost-effective as no support vessel is needed and can travel over long distances. In the current circumstances, the unmanned vehicle also had the advantage of being exempted from quarantine!

“This study was particularly exciting because to our knowledge an autonomous glider has never been used to survey biomass in an offshore wind farm before. As well as the site-specific results, we hope this paves the way for other autonomous studies across industry, which will become more important as wind farms are built further from shore.”

As well as the echo sounder the Sailbuoy is equipped with a temperature and salinity sensor along with a fluorescence sensor. This allows measurement of the fluorescence of chlorophyll, which is good indicator of the presence of a bloom, and therefore food availability to the zooplankton often eaten by fish.

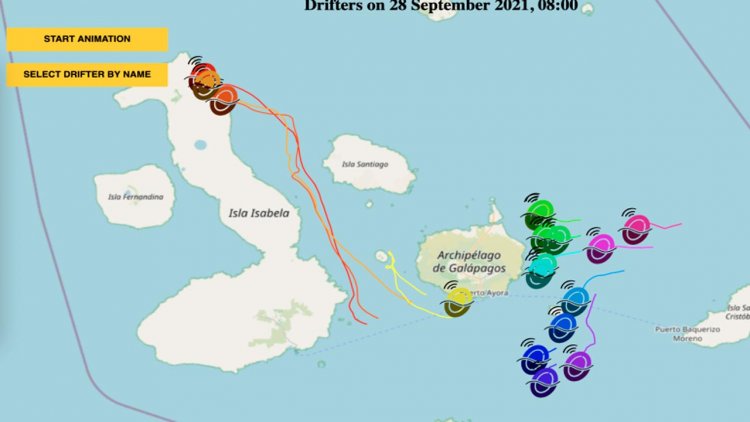

In order to ensure a smooth journey the Sailbuoy was pre-programmed with a mission plan, including positions of the wind turbines to avoid collision. It communicates to shore via satellite, meaning it can be deployed from shore with no vessel needed. GPS means it can be tracked throughout the journey, which took approximately three weeks in total each way. Data was collected on site for around 30 days.

Akvaplan-niva will now analyse the data, and Equinor will use it to understand more about the populations of fish around the wind farm.

In order to progress the development of floating offshore wind, Equinor is gathering all kinds of information from the original floating wind farm, Hywind Scotland, including a collaborative study with Marine Scotland on safe fishing methods, and an e-DNA study in collaboration with NORCE Research.

Facts about the Sailbuoy

- Akvaplan-niva provided and operated the Sailbuoy for the study and will analyse the data on behalf of Equinor.

- It weighs just 60kg and is 2m in length.

- The journey from Bergen to Hywind Scotland took around three weeks

- It has a long track record, including crossing the Northern Atlantic from Newfoundland to Bergen successfully in 2018.

- The Sailbuoy is weatherproof, shockproof and collision proof