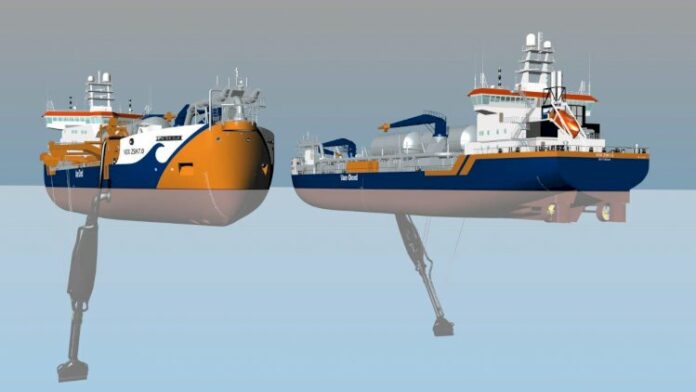

Saipem has signed a memorandum of understanding with Plambeck Emirates LLC, a solutions company in the field of renewables-based in Abu Dhabi, and an exclusive agreement for the development and construction of a floating offshore wind farm.

The project phases will commence in the coming weeks via Plambeck Saudi, a Plambeck company located in Riyadh. The partners will use their experience and know-how to carry out an innovative project, in line with the Vision 2030, the Saudi strategy to promote the development of the country.

Saipem can start operations after finalisation of the financial agreements at the end of the planning phase. The contract will be signed for Saipem to undertake the engineering, design, construction and installation of the entire project and related services.

Francesco Balestrino, Renewables and Green Tech Product Manager of the Xsight division, commented:

"We believe that the wind market in Saudi Arabia can be supported by Saipem technology Hexafloat for the construction of offshore wind farms with an accelerated programme and reduced costs. Initiating the new market in Saudi Arabia is an important opportunity to be seized, and we are ready with Plambeck for this new challenge".

Norbert Plambeck, the shareholder of Plambeck Emirates LLC, stated:

"The development of the 500 MW floating offshore wind farm project is part of the new 5 GW "Wind Market" concept, which has been proposed to Saudi Arabia. We are very proud to have a global solution provider with an international experience like Saipem, with whom we can carry the next development phases of the project. Furthermore, the implementation of the project with Saipem, a reliable international group, is already technically assured".