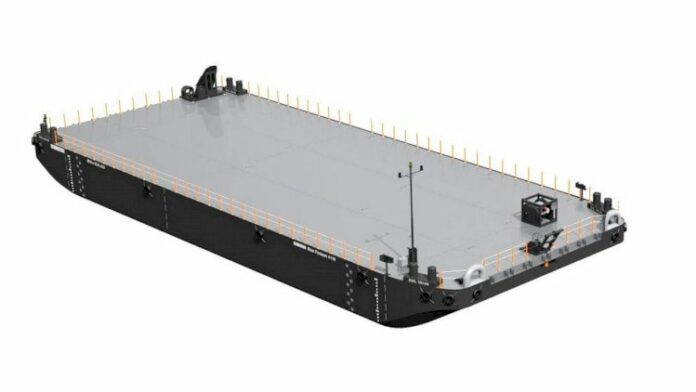

Damen Shipyards Group has signed a contract for the delivery of a pontoon to France-based company, Marc SA. The contract is a significant one for Damen, being the 100th order for a pontoon since the company opened its dedicated Pontoons & Barges product department in 2010.

The client, is a leading civil works company in Brittany, located in Brest, Roscoff, Cherbourg and Lorient and serves the urban, rural, road, rail, maritime, industrial and environmental sectors. Marc SA uses pontoons to carry out its scope of work in the maritime arena, which includes harbour and quayside projects.

When Marc was looking to upgrade its pontoon fleet, it approached Damen, as Damen sales manager Alexandre Richerd explains:

“We already had an existing relationship with Marc; the company is very active in Brest and their pontoons sometimes visit Damen Shiprepair Brest for works and we have hired their pontoons to assist on projects on occasion. We are very much looking forward to continuing to develop this relationship.”

The pontoon will also be used by the Société Cooperatives des Lamaneurs des Ports de BREST et de ROSCOFF, a cooperative society responsible for the berthing, docking and undocking of commercial vessels in the ports of Brest. The region is generally experiencing an increase in civil works projects, combined with the navy and marine renewables activity in the Port of Brest, that has signaled an increase in use of pontoons.

Alexandre:

“We see relatively high demand for pontoons in France generally at the moment; this is the second order in a very short space of time. We look forward to delivering more in the future. Damen will deliver the 100th pontoon to Marc in spring 2020. This is a purpose-built pontoon, which we will deliver to Marc’s requirements. We also build standard Damen pontoons in series for stock, which we are able to deliver in record times.”

Damen builds pontoons for stock from 12 – 145 metres. The stock pontoons are built to proven designs and kept at strategic locations to ensure fast delivery.