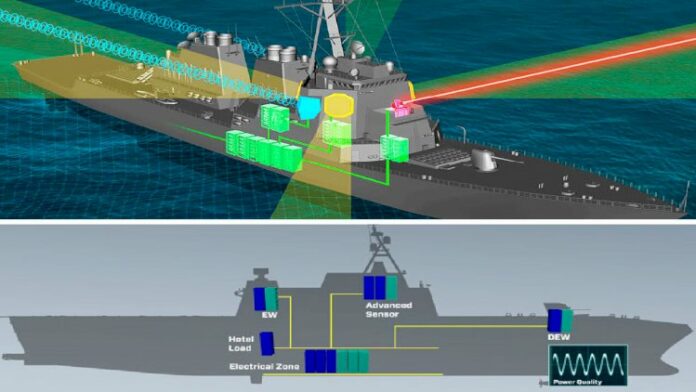

The Integrated Power & Energy Systems (IPES) is a highly dynamic and integrated system which encompasses power generation, distribution, conversion, energy storage and controls. This flexible and scalable system allows modules to be combined for effective power conversion solutions for a variety of shipboard applications, thereby reducing the hardware needed below decks.

Utilizing the next generation of digital controls to enrich the power conversion and energy management capabilities, Northrop Grumman has developed a suite of power solutions using a modular, scalable, and flexible architecture. Northrop Grumman’s solutions can be configured to support a system, a collection of systems, or a complete platform.

For large dynamic shipboard loads, Northrop Grumman has used building blocks to create a modular and flexible Prime Power Equipment (PPE) architecture. The power system is designed to support the wide range of electrical input power that can be present with shipboard systems and to operate within the harsh maritime environment. Additional modules or cabinets can be added as the application dictates. While Northrop Grumman has developed power quality control techniques that have been shown to save 80% or more in required energy storage, systems can be expanded to include additional storage as the mission CONOPS requires.

The embedded machinery control systems take advantage of the lower power, modular electronics building blocks and real-time digital control products. These software-enabled control systems provide a tremendous level of flexibility and control over the machines, incorporating advanced control concepts in coordination with the overall electrical system and network controls. The result is a highly integrated system that is better suited to address transient and dynamic conditions as well as optimize component performance. The resulting reduction in size and weight are highly desirable in an environment where space is at a premium.