The deep, cold waters off the rocky coast of Point Sur, California, are home to an unexpected community of organisms that most people associate with tropical settings—corals.

Scientist Charlie Boch and his colleagues recently compared different methods to restore deep-sea coral by transplanting live coral fragments and measuring their survival rates. The experiment was conducted on Sur Ridge, 60 kilometres (37 miles) offshore and 800 to 1,300 meters (2,624 to 4,265 feet) below the ocean’s surface.

Deep-sea coral and sponge communities don’t receive as much attention as their shallow-water counterparts, but their roles in deep-sea ecosystems are equally as important and, unfortunately, they are just as vulnerable to human impacts, including trawling, mining, and pollution. Scientists have confirmed that human activities in deep-sea habitats are having serious effects on the coral and sponge communities but options to actively mitigate those effects have not been established.

Charlie Boch, an MBARI research associate and lead author on the recently published study, is an expert in shallow-water coral restoration but in this project he’s taking his expertise to the deep sea. Boch said:

“We are inherently connected to deep-sea coral and sponge communities—human societies have been trawling for deep-sea resources for decades. But because we don’t see them in our everyday lives, we may be missing a deeper connection with our oceans.”

MBARI researchers discovered the amazing coral gardens on Sur Ridge in 2013 and since then have worked closely with the Monterey Bay National Marine Sanctuary (MBNMS) to explore and study these ecosystems. Together MBARI and MBNMS have combined their efforts to investigate the best methodology for coral restoration in the deep sea.

MBARI researchers discovered the amazing coral gardens on Sur Ridge in 2013 and since then have worked closely with the Monterey Bay National Marine Sanctuary (MBNMS) to explore and study these ecosystems. Together MBARI and MBNMS have combined their efforts to investigate the best methodology for coral restoration in the deep sea.

This is the first time researchers have attempted to develop and test restoration methods for multiple deep-sea coral species in the Pacific Ocean. Because previous studies have focused primarily on propagating single species, this research helps fill in the knowledge gap for multiple coral species restoration methods in the deep sea. It is also the longest deep-sea coral study ever completed.

Boch said:

“Anytime you do restoration work it is very much a building process—finding out what works, what doesn’t work—but you make an experimental study out of it to tease apart which parts of the process need to be optimized. For this investigation, the team focused on the seven most common coral species living on Sur Ridge, including some of the most iconic and beautiful species: bubblegum coral, bamboo coral, black coral, and precious corals. These species have been harvested in some areas, “jewelry is a common direct human use of coral material from both shallow and deep-sea communities, but thankfully, areas like Sur Ridge are protected from such practices.”

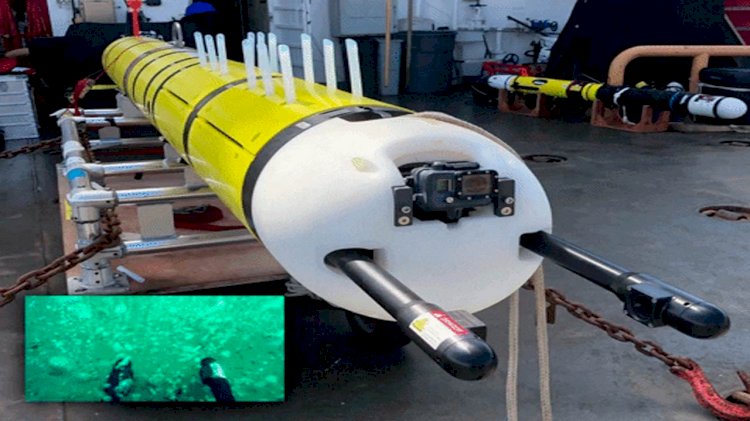

Boch and his fellow researchers collected and relocated corals using one of MBARI’s remotely operated vehicles (ROVs), the Doc Ricketts. They transplanted 113 “coral pots” to eight different locations within Sur Ridge. To create these coral pots, Boch and the team took small branches off living coral colonies, cut them into smaller fragments, and attached them to polyvinyl chloride (PVC) pipes.

Boch added:

“We took a simple approach and did it in an experimental way. We looked at what the next steps in deep-sea coral restoration approaches should be and what we needed to do in order to minimize any stress the corals might experience.”

Boch considers this study a great success:

“Many tropical coral restoration projects have shown that surviving the first year is critical.”

Even in shallow-water coral ecosystems, where decades of studies have already been conducted, few transplanted corals survive as long as a year. In contrast, during Boch’s recent experiment, three coral species had 90 to 100 percent survivorship over three years.

The researchers note that there is no single solution for every deep-sea coral community. Many questions still need answering and methods need testing. For example, are there other strategies that would be more successful for attaching corals to a transportable substrate or module, especially for the species that did not perform well in this experiment? Can these coral species be transferred longer distances, say to an area hundreds of kilometers away? What are the resources and equipment needed for a long-distance, weeklong (or longer) transfer?

Boch said:

“Our goal for this project was to provide some alternative tools for management. Down the line, if ecosystem managers or the public decide they need active mitigation tools to restore these systems after human-induced impacts, such as trawling, the methods and tools will already be available.”