One Sea, the industry alliance bringing together leading exponents of autonomous ship technology, has made a significant addition to its growing membership, after signing up Awake.AI – a company led by an experienced team of maritime digital innovators.

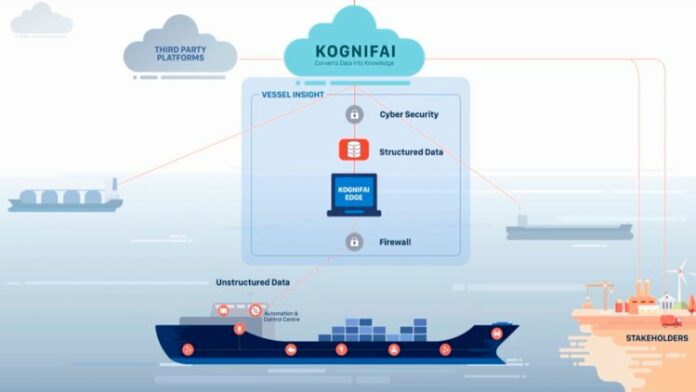

Awake.AI is aiming to create a new platform and ML models (Machine learning) based on transparent data sharing to break down the barriers between ships, ports and other actors in the maritime logistics chain. The ‘virtual infrastructure’ will be vital if ports are to handle autonomous ships successfully from pre-arrival, through cargo operations and to onward departure, according to the Finnish start-up.

Awake.AI CEO, Karno Tenovuo says:

“Today’s data silos result from legacy systems developed when interoperability wasn’t a pressing need. Moving forward, the more information is shared, the greater are the opportunities to automate. Our task is to develop the digital handshakes (APIs) between different supply-chain actors, freeing data to enable smarter ships and ensure their acceptance by smart ports.”

Jukka Merenluoto, Ecosystem Lead, One Sea, commented:

“We are delighted to welcome Awake.AI on board: enabling the smooth flow of data between different players is integral to One Sea’s roadmap to transition from remote monitoring to remote control, and to increasing vessel autonomy by 2025. We also advocate the benefits of maritime digitalisation in its own right, to minimise incidents, decrease marine traffic’s environmental footprint and improve commercial efficiency.”

Drawing on experience from digital innovators that include Nokia, Microsoft, Rolls-Royce Marine, Aker and academia, Awake.AI leverages collective expertise in intelligent and autonomous ship systems, AI data pipelines, system architecture, cloud and network design and cyber security.

Joining One Sea brings Awake.AI into a commercially neutral industry cluster that already plays host to the technology leaders in autonomous shipping, including ABB, Cargotec, Ericsson, Inmarsat, Kongsberg Maritime, MTI, Tieto and Wärtsilä as well as a range of other maritime stakeholders.

Merenluoto says:

“Our membership includes the well-established technology firms making the running on autonomous ships, but it is important we accommodate newer players, like Awake.AI, who can bring fresh perspectives on how to meet the challenges on the road towards realising workable autonomous solutions.”

Awake.AI’s Tenovuo adds:

“Already, we are having conversations with One Sea stakeholders from across the ecosystem to work through strategies to create standards and pathways that will facilitate autonomous shipping.”