Kongsberg Digital, a subsidiary of KONGSBERG, signs an agreement to digitalize the Nyhamna facility, a gas processing and export hub for Ormen Lange and other fields connected to the Polarled pipeline. A/S Norske Shell is entering the partnership as operator of Ormen Lange and on behalf of Gassco as the operator of Nyhamna. The value of the contract scope, with a fully realized dynamic digital twin, is approximately 100 MNOK – with agile and iterative deliverables starting from Q4 2019.

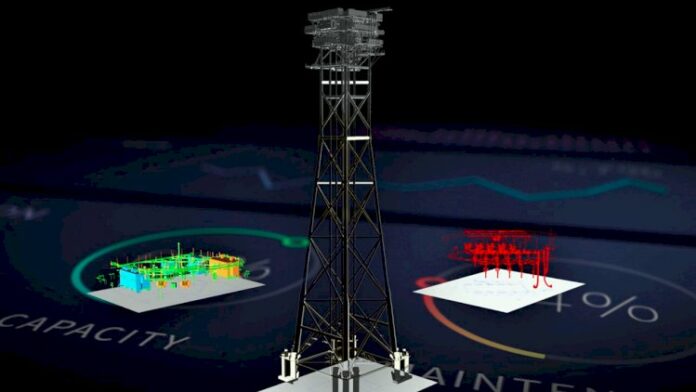

KONGSBERG will utilize Kognifai® Dynamic Digital Twin to establish a dynamic virtual representation of the gas plant and its behavior – continuously updated with integrated information reflecting the status of the facility in real time. As Technical Service Provider at Nyhamna, Shell will be equipped with the ability to simulate scenarios and uncover new options for optimization of its real-life counterpart.

KONGSBERG's Dynamic Digital Twin is an enabler for digitalization of oil & gas assets at scale. Visualization of an asset or a set of assets is one aspect, but the application scope goes vastly beyond this. Kongsberg Digital’s Dynamic Digital Twin will digitally recreate an asset that is continuously updated with contextualized information reflecting the status of the asset in real-time. The key differentiator is our high-fidelity simulators which enable accurate simulation of process data combined with real-time and historical data, enabling advanced machine learning, AI and higher levels of autonomy. With the new digitalized version of the asset, the company who operates or owns the asset will be equipped with the ability to simulate scenarios and uncover options for optimization of its real-life counterpart, whether the goal is increased efficiency, sustainability or safety.