Rolls-Royce is developing an autonomous machinery control system which allows Naval vessels to undertake long endurance missions with less human interaction.

Developed by Rolls-Royce, Artificial Chief Engineer® is a critical enabler for autonomous missions by acting as the equivalent of the engineering department responsible for the health and the operation of an unmanned vessel’s machinery. Navies intend to increase their use of optionally-manned and unmanned vessels to project power further for less cost by reducing reliance on manpower, by allowing higher-risk or longer-endurance missions and by lowering the procurement and operating costs of future platforms.

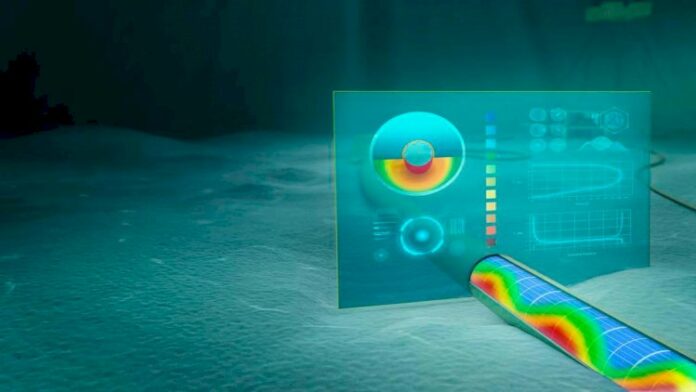

Artificial Chief Engineer is an on-board, secure, decision-making control system designed to intelligently operate the machinery of lean-manned and unmanned naval vessels. The technology makes condition-based decisions about how best to operate the machinery – including the engines, propulsion system, electrical network and fuel system – using algorithms to optimise the ship for maximum efficiency, lowest noise, top speed or to preserve damaged equipment as required by the ship’s mission. This reduces the workload of remote operators and allows increased mission and system complexity in future unmanned ship designs.

Colin Field, Naval Autonomous Systems Engineer at Rolls-Royce, said:

“This project combines our experience with naval ship automation, Rolls-Royce’s knowledge of designing and operating warship power and propulsion systems and our complementary work developing similar autonomous power systems for aircraft.

Now that we have a live Artificial Chief Engineer demonstrator, we want to share and refine our vision of how we believe unmanned vessels should be designed and operated – we want to connect with potential collaborators and help our naval customers realise the benefits of autonomy.”

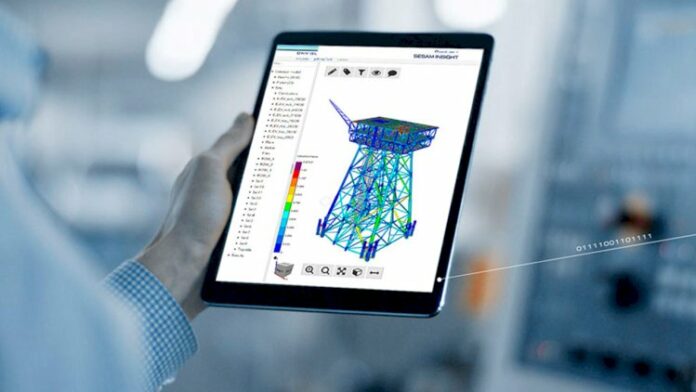

Officially launched at DSEI 2019, Artificial Chief Engineer is currently in the demonstration phase allowing Rolls-Royce engineers to showcase its capabilities using a sample mission that includes fleet escort, open water transit, conducting anti-submarine warfare, managing a complex set of power and propulsion and auxiliary systems and reacting to machinery system degradation.