Blockchain is most widely known as the technology that underpins digital currencies such as Bitcoin. But, blockchain has the potential to transform a whole host of of industries, not only banking. Pilot projects run by the many dynamic companies and organisations based in Rotterdam’s exceptional maritime sector, are already giving us tantalising glimpses of future scenarios.

Martijn Thijsen, Digital Strategy, Transformation and Business Development at the Port of Rotterdam, explains:

“With blockchain, we are already beyond the hype. It’s early stages and there are challenges to figure out. But, we see multiple uses for blockchain technology and the impact potential is enormous. Rotterdam’s ambition is to be the world’s smartest port and we see this technology as key to supply chain optimisation and energy sustainability.”

Stakeholders across the enormously complex logistics supply chain are urgently demanding faster, cheaper and more secure and sustainable flows of goods, services and energy. All this while global trade is becoming more complex and less predictable. Digitalisation has delivered some improvements, but there remains a mountain of documentation, time delays and a lack of interconnectivity. Companies still operate with completely different administrative systems in their own little silo, which can be immensely time consuming and expensive. For example, it can take weeks to trace a single product and all its components through the entire supply chain, and to clarify its origin and ownership at every step in the timeline. A single PO number from beginning to end is typed over more than a 100 times in mails, systems and documents.

Rotterdam’s innovative maritime community recognises that blockchain has the potential to solve such issues and improve the efficiency of supply chain management and port logistics. This open and collaborative eco-system welcomes companies large and small and offers them excellent business opportunities to develop, test and bring blockchain solutions to market.

BlockLab was co-founded by the Port of Rotterdam and the City of Rotterdam. As a Smart Industries Field Lab their role is to put blockchain technology into practice. They are also embedded in the regional innovation ecosystem with the Port Authority and they participate in the Dutch Blockchain Coalition.

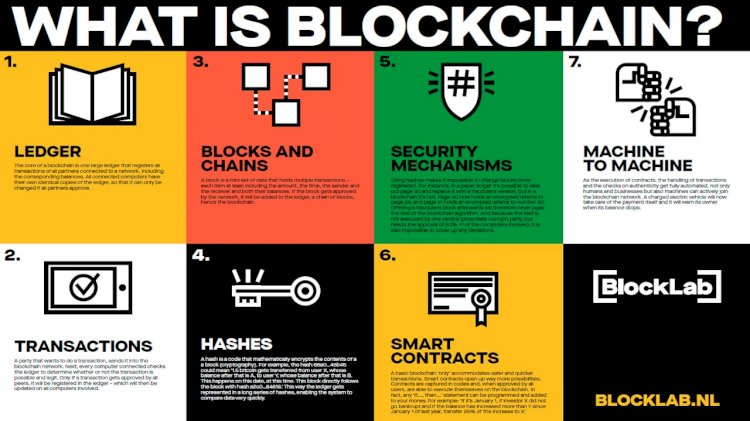

Blockchain is effectively a way of sharing a database securely across a network of computers. It’s often described as a digital ledger or spreadsheet duplicated thousands of times and stored in a distributed network across multiple locations. This network is designed to regularly and instantly update the spreadsheet or ledger, wherever it is located.

Once a record (block of data) has been added to the chain, it is very difficult to change. And, to ensure all the copies of the database are the same, the network makes constant checks. That means digital information can be distributed, but not copied, and the information is constantly reconciled with the database and updated instantly.

Such reliable, public and verifiable records increase transparency and trust. As there’s no central location and the data exists simultaneously in millions of places, it is also more difficult to hack. Effectively, blockchain technology creates a database (shared by every participant in a network) that stores data that can’t be modified without the approval of all members.

But blockchain is more than just making sure that we all look at the same validated dataset. It also makes it possible to jointly agree and execute on the transactions we want to do with that data, without having to worry whether the other party will keep its part of the deal. This allows us to automate the very thorny issue of transfer of ownership as we can remove the catch-22 buyers and sellers face when interacting with each other: “will I get the goods, will I get paid?”.

This system significantly enhances security and traceability. It also reduces or eliminates the need for third parties to verify the exchange of goods and services. This lowers costs and improves efficiency.

Modern logistics networks are decentralised and include many small and medium sized enterprises. The sector is also strongly data-driven and highly dependent on trust, transparency and security. For example, an average of 28 parties are involved in transporting sea containers, and they exchange data around 200 times on any route to ensure a container reaches its intended destination.

Aljosja Beije, Logistics & Technology Lead at BlockLab and co-author of Blockchain and the Supply Chain Concepts, Strategies and Practical Applications, explains:

“Despite massive increases in the volume of international trade over the last 50 years, most of it is still run on documents that go back to the 14th century. We have digitised but, so far, we have not automated. That’s where blockchain will have a big impact.”

Watch Aljosja Beije from BlockLab outline the reasons why blockchain is so valuable to international supply chains.

Lack of trust and inter-connectivity are the main factors behind the current high costs of shipping goods around the world. Each organisation along the supply chain, from banks and customs authorities to import/export companies, have their own systems involving huge amounts of paperwork, a single shipment encompassing over 130 pages of documents, time consuming money transfers, high fraud risk and insurance costs. These processes require constant monitoring and complex financing.

In decentralised networks of companies and institutions, without a single overarching authority, efficient co-ordination and trust is essential. Blockchain not only simplifies processes, it enhances levels of trust because manipulating or deleting data is virtually impossible. As such, the technology could be a critical enabler for secure, controlled and scalable data sharing across the logistics and maritime sector. It would allow logistics service providers to disclose goods, money and information streams flexibly, securely and simultaneously, while reducing costs.

This technology offers the potential, for example, to track and safely monitor the (often perishable) content of sea containers, reduce administrative costs and improve traceability. This is hugely significant. The cost of the documentation required to process and administer goods represents, on average, one-fifth of the costs of physical transport. According to the World Economic Forum*, reducing these barriers could boost worldwide trade by $1Trillion in the next 10 years.

As Europe’s largest and busiest port, Rotterdam is driving the development and implementation of blockchain technology in port logistics. BlockLab is leading the development of these applications by offering blockchain expertise, network and infrastructure to partners.

Aljosja Beije says:

“Blockchain is particularly suitable for collaborative co-ordination. It also suits the way we work here in Rotterdam, where we have a history of forming consortiums to co-create workable solutions. This culture, combined with our outstanding port infrastructure and expertise in digital innovation, makes us the go-to place for partners with similar goals.”

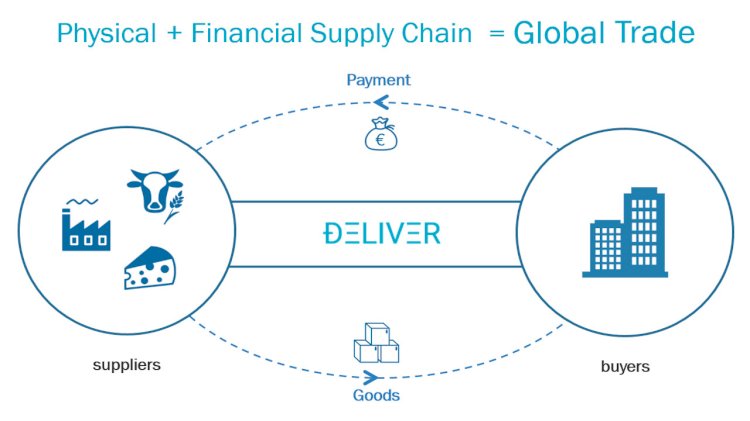

Collaborative blockchain projects can have an immense impact on how we manage supply chains. One example of this is DELIVER. BlockLab partnered with Port of Rotterdam, ABN AMRO and Samsung SDS to develop this pioneering, blockchain-powered supply chain management platform.

Eric-Jan Iding, Marketing Manager at Samsung SDS, explains:

“What we have co-created with DELIVER is an open and neutral industry platform that optimises both the physical and financial supply chain. DELIVER fixes the supply chain’s trust and transparency problem by enabling a more transparent, efficient, predictable and secure exchange of information. It tracks orders, shipments and finance in real time, improves data sharing, reduces risk and enhances interoperability.”

In July 2019, two containers from South Korea arrived at the Samsung SDS warehouse in Tilburg, the Netherlands via the Port of Rotterdam.

Martijn Thijsen at the Port of Rotterdam says:

“The shipment was completely paperless, instantly financed and door-to-door tracked using DELIVER. Integrated container tracking meant everyone could always see where they were, documents were always accessible and everything, right up to proof of delivery, was put automatically into the DELIVER blockchain.”

The success of this project has proved that blockchain technology can enhance supply chain transparency and efficiency, and potentially unlock millions of euros in cost savings. But, these first containers were just the Proof of Concept phase. Aljosa explains:

“We’re developing extra functionalities and capabilities for the platform.”

Eric-Jan says:

“We’re now extending the DELIVER pilots with external companies on various trade lanes. Ultimately, our goal is to facilitate transparency, eliminate barriers to trust and reinvent global trade.”

Energy is another high dependency sector for the maritime industry that is particularly suitable for blockchain innovation. The transition to sustainable energy, with a decentralised network of wind turbines and solar panels, is resulting in increasingly complex power supply and consumption models.

Together with S&P Global Platts, BlockLab is also building a platform that coordinates the supply and demand of energy. This energy platform is complete in principle and the first practical tests are about to start in the Innovation Dock in Rotterdam where the Port Authority has its own site with smart energy meters. The most important thing is that big organisations gain confidence in blockchain. They need to dare to take the step to using this on a large scale.

BlockLab has also supported the development of four blockchain technology prototypes that coordinate a flexible trading platform to continuously align supply with demand. These prototypes range from smart meter identities to smart Power Purchase Agreements and two are already receiving market readiness support.

In addition, BlockLab stimulates research in the blockchain community through its Open Energy Hub. This virtual energy lab connects energy pioneers´ smart meters to an online development community.

In addition, BlockLab stimulates research in the blockchain community through its Open Energy Hub. This virtual energy lab connects energy pioneers´ smart meters to an online development community.

Janjoost Jullens, Energy Lead at BlockLab, explains:

“Currently, one group is developing a fair data marketplace and another is preparing the first user driven case studies,”

This provides an open source data platform connected to several hundred smart meters for other parties to experiment on. BlockLab takes care of the blockchain infrastructure so parties can run their applications on live data.

Martijn Thijsen says:

“Rotterdam has long been a frontrunner in digital innovation and collaboration. Our whole ecosystem is based on being one-step ahead. We want to lead in digital, as well as physical infrastructure, and to achieve that we need to co-create with our partners and become a globally connected smart port. Rotterdam’s focus on innovation puts us in an ideal position to be able to collaborate and facilitate across the global supply chain.”

Pilot projects, such as DELIVER, have proved the potential for blockchain, integrated with other IoT and AI-enabled technologies, to drive a wholesale reimagining of the global logistics industry. Rotterdam’s maritime innovators have shown it is possible to break down many of the common barriers in supply chains and securely digitise and automate many processes.

Leading research institutions, such as SmartPort Rotterdam, a living lab where applications are developed and put into practice, are now exploring future blockchain applications. The knowledge gained in this living lab, will determine future opportunities for harnessing blockchain in port logistics. There will be steep learning curves. And, many technical, legal and cultural hurdles to overcome.