As a result, VSTEP can now supply RH Marine’s ECDIS chart and navigation system with its bridge simulators for schools, training institutes and fleet owners.

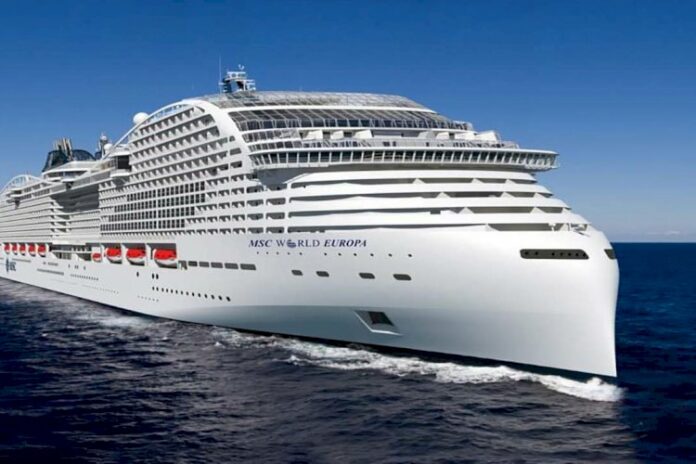

VSTEP supplies software and hardware for NAUTIS simulators around the world from the Middle East, Southeast Asia and Europe, but also in North, Central and South America. Realistic bridge training is made possible on advanced simulators that place trainees in immersive virtual environments. RH Marine supplies electrical and automation systems to defence, safety and security ships and superyachts, including complete bridge systems.

One of those systems is the electronic chart display and information system ECDIS, a so-called TomTom Navigation at sea. This system is mandatory on every seagoing vessel. Ties Klapwijk, Head of Business Development NAUTIS at VSTEP Simulation, says:

“We are two Dutch companies whose products complement each other very well. Thanks to this cooperation, RH Marine’s ECDIS system is now included in our portfolio for customers. We are very happy with that option.”

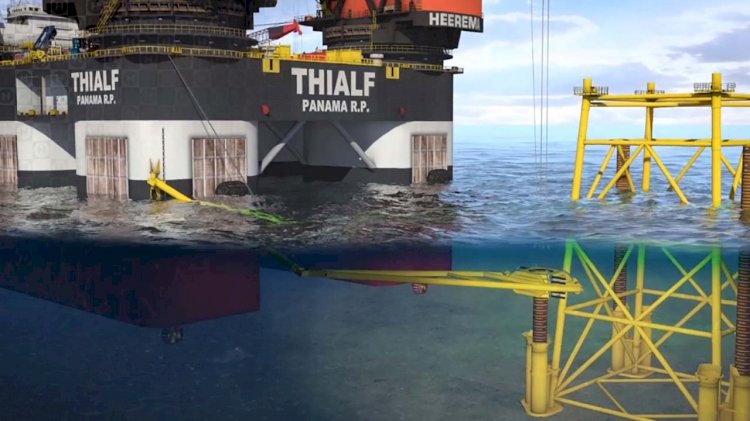

Both companies have teamed up before, for instance for the Offshore Experience of the Maritime Museum in Rotterdam. With this simulator, visitors must, among other things, keep a DP ship in place. VSTEP made its simulator software available for this and RH Marine did so with its DP software. VSTEP also supplied the VR software for the RH Marine Demonstrator, with which the company demonstrates the operation of its bridge systems to customers and during trade shows. That software is now being upgraded as part of the cooperation.

Last year, both companies worked together on the new bridge simulator at the Royal Institute for the Navy (KIM) in Den Helder. For this simulator RH Marine also supplied the chart and navigation software and VSTEP supplied the 360 degrees virtual outside view.

The closer cooperation has various benefits for customers and companies. RH Marine customers will soon be able to virtually train their ECDIS skills in more locations anywhere in the world. In addition, customers from outside the naval and superyacht industry can also get acquainted with its ECDIS system.

Portfolio manager Marcel Vermeulen of RH Marine says:

“Although leading, we operate in a niche market. This increases our availability and visibility abroad. Moreover, as more people start using our system, we can receive more feedback. As people increasingly come into contact with our system during their education or training, the better known it becomes with our target group.”

According to Klapwijk, the cooperation also offers benefits in case of service or malfunctions. He says:

“Because we are based close together and the lines of communication are short, we can react quickly.”