NAPA, the leading maritime software, service and data analysis provider, alongside leading classification society, ClassNK, and Mitsui O.S.K. Lines, Ltd. (MOL), has announced that the software they have been collaborating on to intelligently monitor and mitigate grounding risks has been verified as successful in its proof-of-concept stage. Following the proof-of-concept stage, MOL, NAPA and ClassNK have agreed to the joint further development for a comprehensive navigational risk monitoring system.

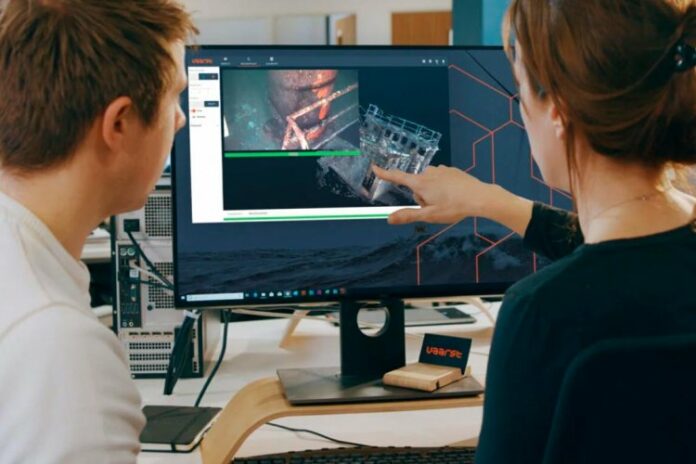

The grounding risk monitoring system, which is based on ship performance monitoring and voyage planning platform, NAPA Fleet Intelligence, combines many data sources, such as position data, sea depth and navigational charts, to provide a robust and accurate fleet-wide platform to reduce grounding risk. The system also provides carefully calculated alerts and notifications to crew onboard, as well as those onshore if vessels operate in a high-risk way, strengthening ship-shore connectivity and enhancing response time.

The development of the vessel grounding risk monitoring system could help reduce future grounding incidents and increase the shipping industry’s safety standards.

In the proof-of-concept stage, in collaboration with MOL, NAPA tested algorithms and warning mechanisms by using them to analyse historical vessel movements, proving that the system would have been able to mitigate against any past incidents in this sample.

The project also saw ClassNK apply their expertise throughout the entire process, while NAPA applied its big data expertise with MOL during the proof-of-concept phase. All parties played an important role in evaluating the concept in practice, distinguishing an effective, easily implementable, affordable grounding risk monitoring software solution for fleet-wide application.

Based on the results of the proof of concept, an integrated risk monitoring system for operation, including monitoring of stranding, is also being developed. The new system will monitor risk factors such as the formation of volatile or unpredictable weather on a vessel’s given route. Additional technologies to monitor risk while anchored or moored are also currently being developed.

Commenting on the collaboration, Naoki Mizutani, Managing Director at NAPA Japan, said:

“The development of this software marks a new frontier in the intelligent application of big data in reducing grounding out at sea and other navigational risks. The success of the proof of concept with our valued partners, MOL and ClassNK, reinforces the value of big data analysis in enabling more informed decision making to increase safety and efficiency.”

Satoshi Fujii, General Manager of MOL’s Smart Shipping Division, said:

“We are very pleased with the results of the proof-of-concept stage of the vessel grounding risk monitoring software, in collaboration with NAPA and ClassNK. With the proof-of-concept stage having been made possible within a limited time frame, re-affirming both NAPA’s and ClassNK’s technical capabilities as a result of an effective and practical monitoring system – we are looking forward to developing and implementing this system to our vessels in order to ensure the safety of our fleet.”

Dr. Toshiro Arima, Corporate Officer and General Manager of Digital Transformation Center at ClassNK also commented:

“Collaboration is key to enhancing safety and increasing efficiencies. With that being said, we are glad we have combined our diverse expertise to extensive operational data for the successful creation of a fleet-wide solution to reduce vessel grounding risk. Following the contribution by our expertise to the proof-of-concept, we hope to continue being involved in the system also from the standpoint of verifying its function and effectiveness.”