Ms Karin Schinagl, wife of Managing Director Netherlands Ronald Schinagl, named the vessel Maas. Ms Karien van Oord performed the naming ceremony for the Mersey. Until 2020, she was the chair of the Van Oord Family Council and a member of the MerweOord Board of Directors.

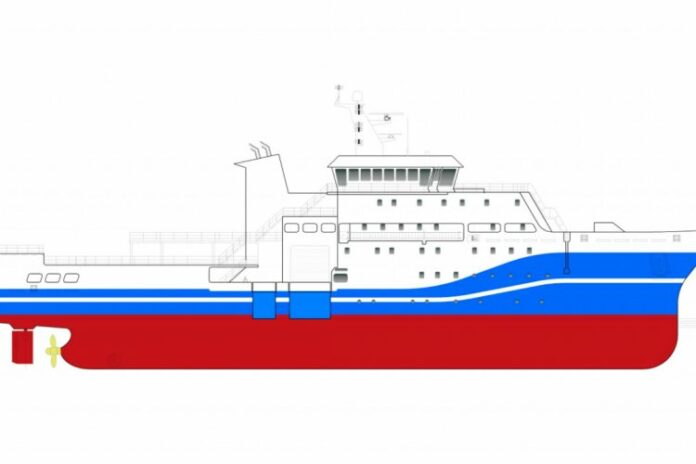

The Maas and Mersey represent the new generation of hybrid water injection vessels. This new vessel type is versatile and has water injection dredging, mass flowing and power jetting systems. Water injection dredging is an efficient and environmentally friendly way of maintaining the depth of navigation channels, ports, marinas and rivers. For over 30 years Van Oord has been using this technique all around the world.

The latest technological developments have been applied to both vessels, such as active heave compensation and dynamic positioning, which means that the dredging can be pre-programmed to a great extent and performed more efficiently. Thanks to the maneuverability and very limited draught, the vessels are perfectly suitable for maintenance dredging in shallow harbours At the same time they can dredge up to 24 metres water depth and are certified as unrestricted seagoing vessels.

The energy management of both vessels was given special attention. Both vessels are equipped with a hybrid energy management system. Consequently, the vessels can store energy in batteries from residual heat that is normally lost. This energy is subsequently used for purposes including propulsion. Diesel-electric engines will reduce CO2 emissions. The new water injection vessels will comply with the new IMO TIER III legislation for reducing NOx emissions and take account of EU STAGE V legislation. The vessels were delivered by Kooiman Marine Group in Zwijndrecht, the Netherlands.

The two vessels were ordered in 2019 and are part of the Van Oord’s fleet investment programme. Maas and Mersey will replace the first generation of WIDs, which were put into service around 1990. The investments in a modern and energy-efficient fleet demonstrate Van Oord’s confidence in the future for dredging.

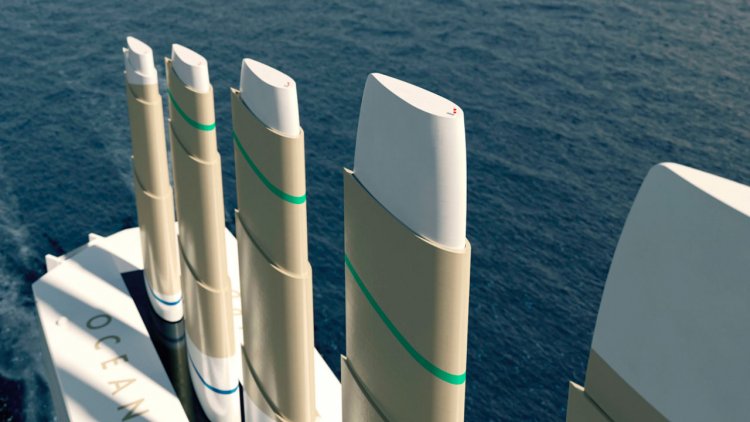

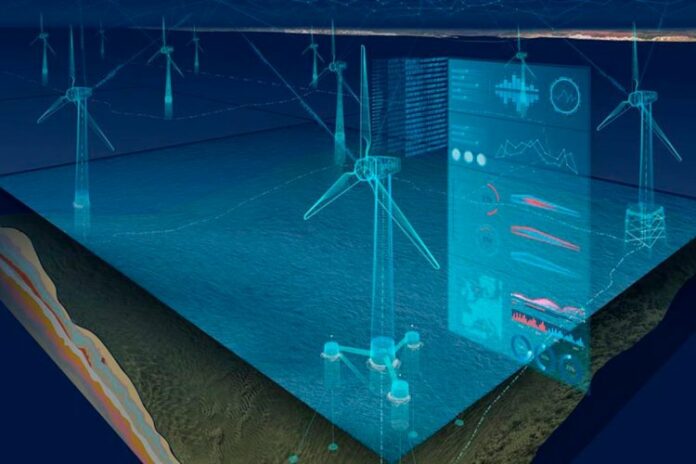

To become carbon neutral by 2050 – which is Van Oord’s ambition – Van Oord faces a major challenge and opportunity in terms of finding new fuel technologies for its fleet and adapting its operations accordingly. Steps have been made in its investment programme with the construction of three LNG-fuelled trailing suction hopper dredgers and the ordering of a new green cable-laying vessel with the latest sustainable technologies in order to reduce the carbon footprint.