ACRRI is a world-first biodiversity approach that is transforming global efforts to promote coral reef recovery.

The five-year national research program brings together research from two World Heritage sites – the Great Barrier Reef in Queensland and Ningaloo Reef in Western Australia – to develop new and innovative methods to improve the resilience of coral reefs and mitigate the effects of climate change.

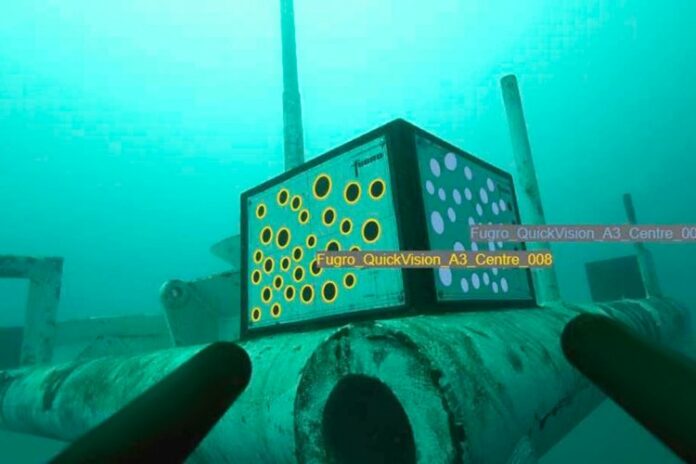

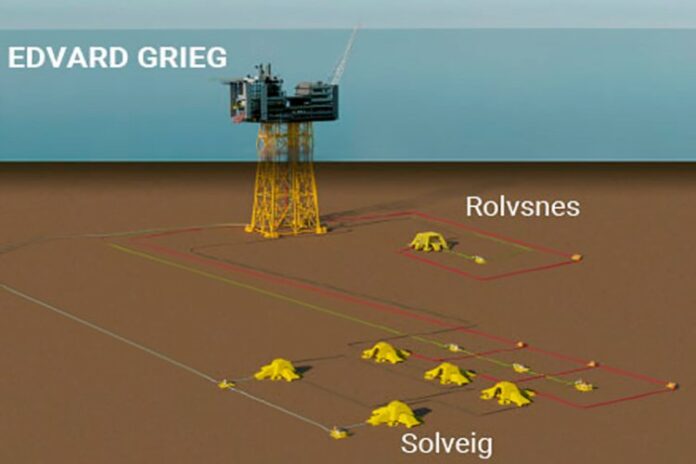

ACRRI involves a two-fold approach using underwater acoustics to mimic the sounds of healthy reef ecosystems to lure fish to reefs that are being replenished using the latest coral re-seeding techniques. This could be a winning combination in global efforts to help reefs become more resilient to warming ocean temperatures.

AIMS CEO Dr Paul Hardisty said the research program sought to speed up the natural process of tropical reef growth and recovery by simultaneously investigating both coral and fish reproduction, their early life survival, and the relationship between the two.

He said:

“This is the first time in the world that coral restoration research is exploring whether attracting more fishes to settle on a reef positively influences the settlement and growth of coral after fertilisation.”

Dr Hardisty said disturbances on tropical reefs were increasing in frequency, severity and duration leaving corals with less time to recover:

“This research will lay the foundation for a completely novel ecosystem-based approach to influence the size of future adult populations and the amount of coral cover on a reef. It will be a global game-changer.”

BHP Chief Technical Officer Laura Tyler said BHP was pleased to continue its long-standing partnership with AIMS and contribute to the resilience of the natural environment.

She said:

“Coral reefs are essential for the healthy ecosystems the world depends on for clean air and water and productive landscapes and seascapes.”

“The Australian Coral Reef Resilience Initiative is a wonderful opportunity for BHP to work with some of the world’s leading marine scientists right here in Australia, to tackle a challenge affecting the health of our precious marine environment all over the world.

“Our goal is to have made a measurable contribution to the conservation, restoration and sustainable use of marine and terrestrial ecosystems in all regions where we operate by FY2030.”

The AIMS research team in Ningaloo will explore the role of fish settlement, husbandry and herbivory in promoting ecosystem recovery.

Dr Hardisty said:

“We know from a proof-of-concept study that soundscapes of healthy reefs are settlement cues, with fishes choosing a healthy-sounding reef over a degraded reef.”

The AIMS research team on the Great Barrier Reef is investigating the process of coral seeding, survivability and growth, to reduce high mortality during their first year of life.

Currently underway, in the Keppel Islands through a partnership with Woppaburra Traditional Owners, the research team incorporates traditional ecological knowledge with western science and creates skills and employment pathways in coral aquaculture for Indigenous Australians.

Dr Hardisty said ACRRI maximised the benefits of both seeding and growing corals at scale and attracting fish to settle on an impacted reef, to enhance reef recovery and adaptation.

He said:

“Marine science, along with reduced emissions, can play a significant role to protect Australian coral reefs from the escalating effects of climate change, helping them adapt, recover and survive warming ocean conditions.”