The global shipping industry is responsible for ~2.9% of global greenhouse gas emissions, which equals almost 1 billion metric tons of CO2 each year. Unchecked, emissions could increase by as much as 130% from 2008 levels by 2050.

Transitioning to low-carbon fuels will be essential to secure the long-term future of the industry and meet International Maritime Organisation (IMO) emissions reduction targets for 2030 and 2050, but still-developing technologies and the long lifetime of existing vessels makes this an even bigger challenge. Currently there are more than 70,000 vessels travelling our oceans, with an average lifespan of approximately 25-30 years. Finding a low emissions fuel for these vessels is no easy task, but now is the time to accelerate the transition. Methanol offers not only immediate, and urgently required, benefits but the only clear pathway to a sustainable future.

Proman, one of the world’s largest producers of methanol, has together with Stena, a privately owned shipping company operating approximately 140 vessels, decided to take on this challenge. Proman and Stena are committed to jointly developing a Retrofit & Supply solution, enabling both Stena’s vessels as well as third party vessels to experience the immediate environmental benefits and greenhouse gas emission reductions delivered by methanol.

By switching to this clean-burning fuel, methanol-powered vessels can lead the transition to a lower carbon future and significantly reduce the greenhouse gas emissions generated by conventional oil-based fuels, bringing an immediate improvement in air quality around ports and shipping lanes. Sulphur oxides (SOx) and particulate matter emissions are practically eliminated, carbon dioxide (CO2) emissions reduced, and nitrogen oxide (NOx) is cut by ~60%. Furthermore, methanol’s biodegradable and water-soluble qualities significantly reduce the risk to marine environments.

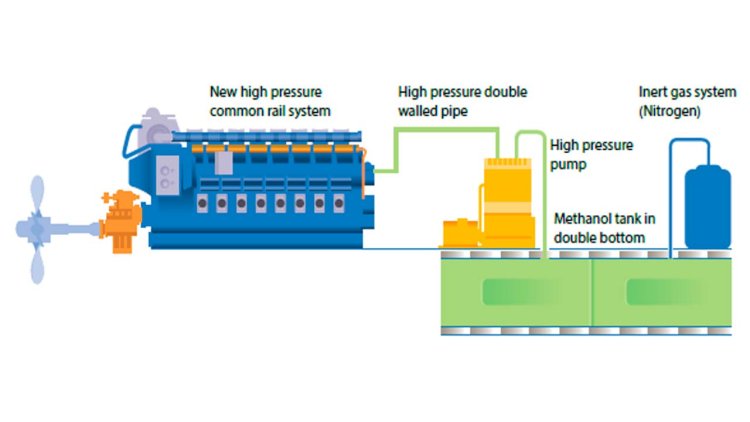

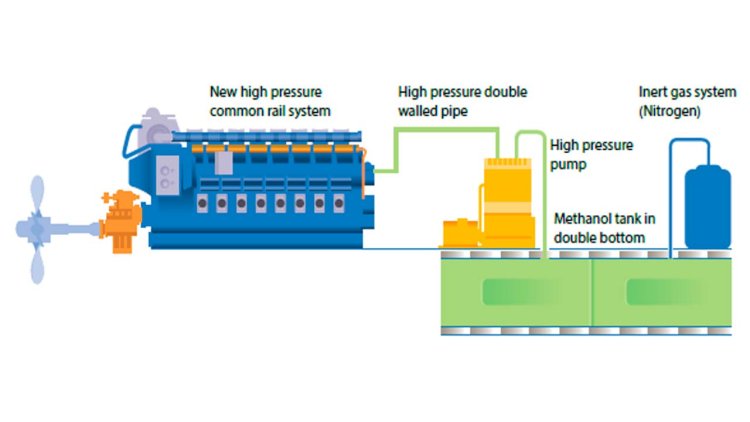

Proman and Stena have uniquely complementary skills enabling them to jointly offer a turn-key solution for the shipping industry to benefit from a methanol-based pathway to a sustainable low-carbon future. In 2015 Stena was the first ship owner in the world to convert a large vessel to methanol power together with a current partner. Since then, the vessel has been operated safely and conveniently, thereby demonstrating the potential of using methanol as a marine fuel. Methanol produced from natural gas brings an immediate CO2 reduction which will be further reduced to over 90% as renewable and sustainable methanol becomes more widely available as marine fuel.

Per Westling, CEO, Stena RoRo, said:

“We believe that methanol is a clear frontrunner in shipping’s search for fuels beyond the fossil default and we are proud to be playing our part to help build the market for alternative fuels within shipping. We converted Stena Germanica to methanol power already in 2015 with another current partner, and that gives us valuable experience both from a conversion and operational perspective.”

The plans for a Retrofit & Supply solution build on the previously announced joint venture between Stena Bulk and Proman for three methanol-ready tankers. The first of these vessels, the 49,900 DWT Stena Pro Patria will be delivered in early 2022, with a further three Proman-owned but mutually operated dual-fuel vessels due in 2023.

Carl-Johan Hagman, CEO, Stena Rederi, said:

“This announcement builds on the exciting and fruitful partnership that Stena Bulk has already forged with Proman and gives Stena another avenue to explore the use of methanol on more ship types.”

David Cassidy, Chief Executive of Proman, said:

“Methanol is the only available alternative marine fuel that offers immediate emissions reductions, dramatically improving air quality and delivering a clear shipping decarbonisation pathway for 2050 and beyond. Unlike other alternative marine fuels, methanol utilises existing technology and is safe and widely available. Proman’s partnership with Stena has grown from strength to strength. Our combined vision is to dramatically accelerate the energy transition in shipping and not only talk about changing our environment but to actually make it happen. We will leverage both companies’ ambition and expertise to make methanol more widely available to vessel owners around the world and help them to join us on the transition to a cleaner shipping industry.”