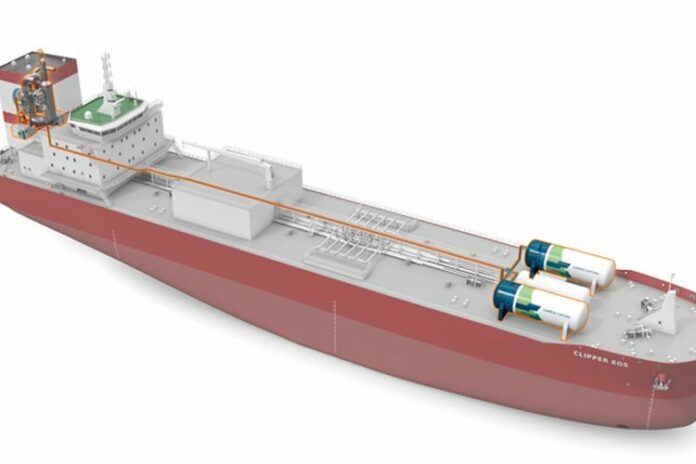

Wärtsilä Exhaust Treatment and Solvang ASA, a Norwegian shipping company, have agreed on a full-scale pilot retrofit installation of a carbon capture and storage (CCS) system on one of Solvang’s ethylene carriers, the 21,000-cbm Clipper Eos.

Wärtsilä Exhaust Treatment designs the retrofitted unit while it also completes a land-based 1MW test system at its Moss headquarters in Norway. The land-based unit will be completed in autumn 2021, and the companies expect to retrofit the pilot CCS system on the Clipper Eos by 2023.

The agreement reinforces Wärtsilä’s continued research and development into carbon capture at the point of exhaust to support the shipping industry’s decarbonisation pathway.

The project will enable both Wärtsilä and Solvang to strengthen their position at the cutting edge of sustainable technology development in shipping. To remain in line with the IMO’s decarbonisation targets, Wärtsilä is initially aiming for a 70% reduction in CO2 emissions at the point of exhaust with its pilot unit.

Commenting on the announcement, Sigurd Jenssen, Director at Wärtsilä Exhaust Treatment, said:

“Joining forces with Solvang to build and retrofit a commercially viable CCS technology demonstrates to the industry that we are only two or three years away from bringing to market another vital tool in shipping’s decarbonisation toolkit. We are excited to see how this collaboration with Solvang evolves in the coming months. Our land-based test unit is nearing completion, and we will then move to making it a reality on the Clipper Eos, ensuring that both Wärtsilä and Solvang remain at the forefront of maritime sustainability technology advancement.”

Edvin Endresen, CEO at Solvang ASA added:

“Carbon capture and storage is an exciting development that we are proud to support, and strongly believe that this technology could be an important key to decarbonize the world’s deep-sea fleet. As a forward-thinking company that is equally passionate about ensuring the industry’s transition to decarbonisation, Wärtsilä is the perfect partner as we look to scale up sustainable technologies across our fleet and reduce shipping’s environmental impact on the world.”

The vessel, “Clipper Eos” has been time chartered by Marubeni Corp., Tokyo since her delivery from the shipyard in 2019. Marubeni, having more than 40 years’ experience trading and handling ethylene, advise that they are committed to cooperating with Solvang and Wärtsilä to enable the parties to perform relevant testing and installation of equipment on the vessel in a mutual effort to drastically reduce the CO2 footprint of the vessel.

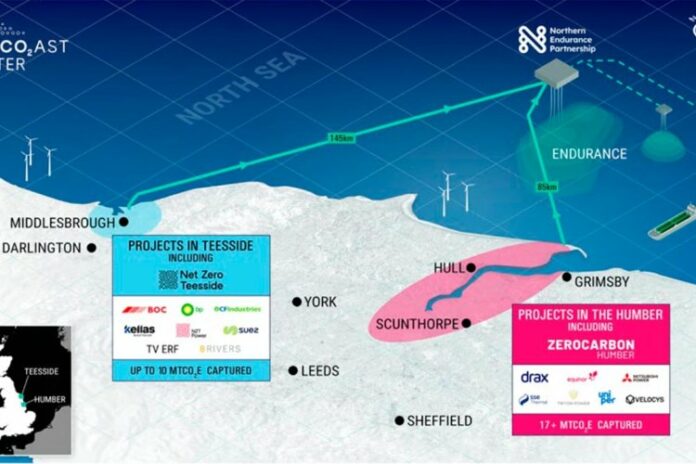

In addition to signing a Letter of Intent with Solvang and scaling its Moss CCS test unit, Wärtsilä recently announced it is partnering with the LINCCS consortium to scale and create carbon capture technologies and infrastructure. The consortium recently received 111m Norwegian Kroner in funding to CCS research and development.