Fincantieri Bay Shipbuilding has agreed to partner with PNE Marine Holdings (“PNE”), an affiliate of Polaris New Energy (“Polaris”) to build a second 5,500 cubic meter (CBM) LNG bunker barge.

This new barge will be a sister vessel to the LNG bunker barge Clean Canaveral, which will deliver to Polaris in mid-November.

Fincantieri Bay Shipbuilding is the main commercial business unit of Fincantieri Marine Group in the United States. FMG’s president and CEO, Dario Deste, offered the following on the contract announcement:

“Our team at Fincantieri Bay Shipbuilding is once-again showing why they are the U.S. market reference point for LNG bunkering vessels.”

Demand for economical supply of LNG fueling the maritime sector is growing rapidly. Over the next several years 400 new vessels utilizing LNG are expected in service. LNG is the leading solution to fuel the maritime sector as the industry advances its sustainability goals through a transition to lower carbon fuels. The new articulated tug and barge adds to Northstar’s growing fleet delivering LNG to cruise ships, container vessels, bulk carriers, car carriers, and tankers that are in service or on order today.

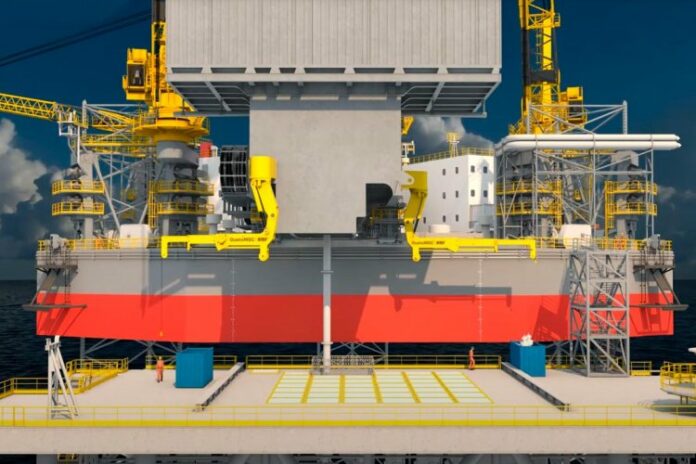

The 5,500 cubic meter ATB will be fitted with four 1,375 CBM IMO Type C tanks. It will utilize a cargo handling system designed and developed by Wartsila. Upon completion, the vessel will be 340’ overall length, 66’ beam, and 32’-10” deep. The ATB will be an Oceans Classed ABS barge.

Todd Thayse, Fincantieri Bay Shipbuilding’s Vice President and General Manager said:

“Thanks to our continued partnership with Northstar and its affiliate companies, we are amassing our extensive in-house expertise in the design and construction of LNG bunker barge capabilities. As we begin constructing our second LNG bunker barge for Polaris, we are excited to bring the expertise of Fincantieri, our bunker barge design knowledge, and our passion for delivering the highest quality, on-time products to the LNG market. The hard-working, proud women and men of Fincantieri Bay Shipbuilding will once again provide the quality and eventual on-time delivery the maritime industry has come to know and expect from our shipyards.”

Tim Casey, Senior Vice President – LNG for Northstar, said:

“LNG is recognized as a clean, dependable and competitively priced fuel for the shipping industry. The completion of this sister vessel to the Clean Canaveral further distinguishes Northstar’s capabilities to manage the last-mile logistics of LNG safely and effectively across the US coastline. The new capacity will provide unmatched reliability and flexibility in the current market and is the next step in our strategy to create a complete platform of LNG logistical solutions for marine customers.”

Tim Casey continued:

“We’re excited to be moving forward on the second barge with Fincantieri. They proved to be the right partners to build the Clean Canaveral. Despite the global challenges of the last two years, they have performed above expectations and we are confident that they’ll do the same with this second barge as they leverage their unmatched experience gained during construction of the Clean Canaveral.”

PNE and Polaris are subsidiaries of Northstar Terminals, a portfolio company of funds managed by Oaktree Capital Management, L.P. (“Oaktree”).