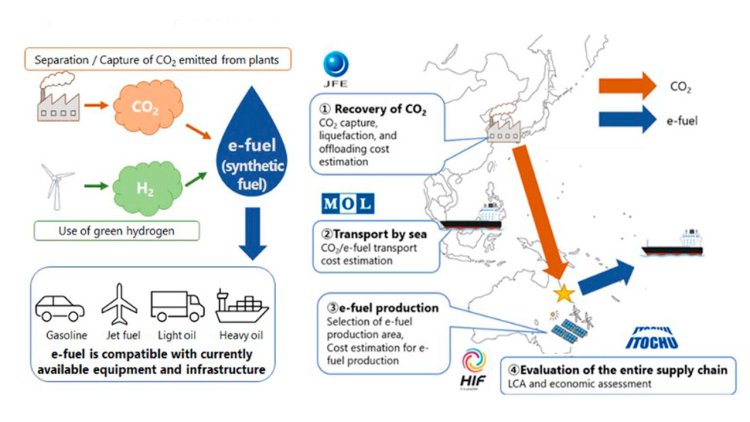

HIF Global, ITOCHU Corporation(ITOCHU), JFE Steel Corporation and Mitsui O.S.K. Lines (MOL) have announce an agreement to identify and assess potential locations for carbon neutral eFuels facilities in Australia and investigate the establishment of a CO₂ supply chain between the two countries.

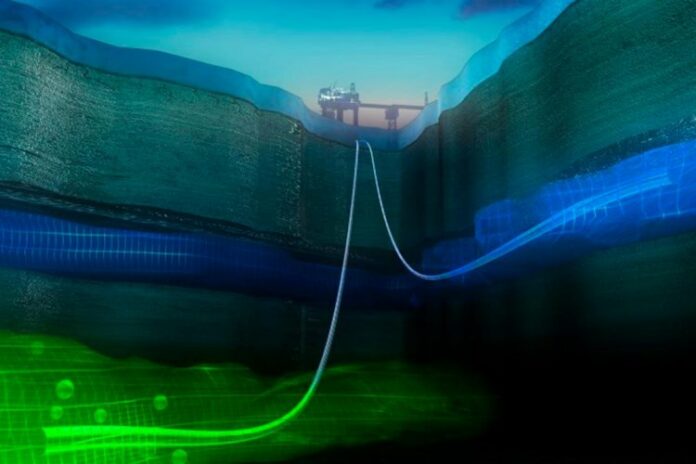

HIF will identify sites in North Queensland to host commercial-scale, cost-efficient eFuels facilities and evaluate importing CO₂ for use as an eFuels feedstock. ITOCHU will be responsible for lifecycle assessment and economic assessment. JFE will study the capture and storage of carbon dioxide in Japan. MOL will analyse shipping both CO₂ from Japan to Australia and eFuels from Australia.

Ignacio Hernandez, HIF Asia Pacific’s CEO, said:

“The cooperation agreement between HIF, Itochu, JFE Steel, and MOL demonstrates the strong demand for eFuels to decarbonize transport around the world now. Our collaboration is a critical enabling step toward commercialization of the natural synergies between Australia and Japan as we work together to tackle climate change. HIF produces eFuels today in Chile and has a large-scale facility in Texas due to enter construction this year. Our Tasmanian eFuels project was one of only six to be shortlisted for the Australian Government’s Hydrogen Headstart funding program two months ago, and now we initiate the site selection process in Queensland.”

Jun Inomata, Executive Officer, ITOCHU (Chief Operating Officer, Metal & Mineral Resources Division), said:

“One of the basic policies of ITOCHU’s medium-term management plan is to contribute to and strengthen initiatives for the SDGs, and through this initiative, ITOCHU will contribute to the realization of a decarbonized society by building an eFuel supply chain. All four organizations in this collaboration will leverage their networks in Japan and overseas and the knowledge they have accumulated through their business in Australia to build an eFuel supply chain, starting with JFE Steel, with an eye towards a decarbonized society.”

Yasuchika Noma, Executive Officer of MOL, said:

“MOL is honored and excited to have an opportunity to collaborate with HIF Global, ITOCHU and JFE Steel. We believe this cooperation will make a significant synergy to create CCUS value chain between Australia and Japan, and also hope to expand our collaboration to wider areas of solutions for decarbonization.”

eFuels are made using electrolyzers powered by renewable energy to separate hydrogen from oxygen in water. The green hydrogen is combined with recycled carbon dioxide to produce carbon neutral eFuels, which are chemically equivalent to fuels used today and can therefore be dropped-in to existing engines without requiring any modifications.

The term “e-fuel” refers to liquid fuel produced by synthesizing hydrogen produced from renewable energy sources and CO2. The CO2 feedstock will be CO2 emitted from industries that will have difficulty achieving decarbonization through electrification, hydrogenation, and other means alone. A benefit of e-fuel is that it can use current infrastructure such as vessels, lorries, storage tanks, and fueling stations for transport and storage. In addition, e-fuel itself can be used to power automobiles, aircraft, and vessels without the need to modify or replace current equipment, so its use is expected to be an early decarbonization measure.