Sources at Naval News reported that the submarine, captured on camera during a sea trial, is being tested off the coast near La Spezia, Italy.

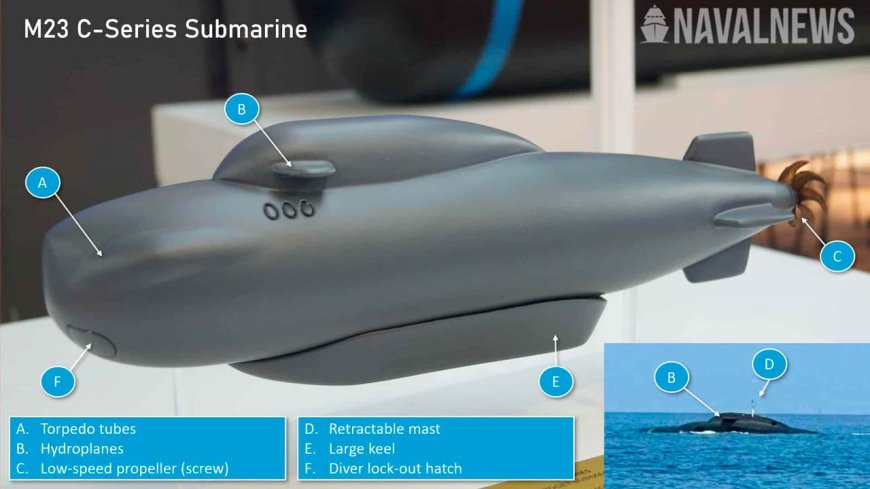

Fresh details of Qatar’s new submarines have been revealed at the MSPO International Defence Industry Exhibition in Poland. The two submarines for the Qatari Emiri Navy are being built by M23 SRL in Bergamo, Italy. The exhibition included a model of the C-Series design, the first time it has been shown in public.

The M23 C-Series submarine has also been observed being tested at La Spezia, the physical and spiritual home of Italian naval special forces. The port has a long and storied tradition of midget submarine construction, both for the nation’s special forces and export.

The submarines were contracted in January 2020 under a deal associated with Italy’s main defence shipbuilder, Fincantieri. The agreement described “the supply of cutting-edge naval vessels and submarines.” Now it is becoming clearer what those submarines will be.

The submarines have been constructed at Ciserano, Bergamo, far inland, 100 km (60 miles) east of Milan. They will have been transported by 250 km (150 miles) road to the coast. The physical confines of the factory in Ciserano, together with the need to transport the submarine by road, limits the size of the submarine.

Previous images of the submarine, reported by us in May 2021 provided some hints to the submarine’s capability. As built, the submarine has a slick superstructure and sliders keel not seen on the previous illustrations. This superstructure is typical of the boats designed by famed naval architect Giunio Santi. Despite its differences, it is clear that the previously shown design is closely related to what we are seeing in the latest model, and in the water.

Santi began building submarines in the 1970s and gained a reputation for high quality and innovation. He pioneered air-independent power (AIP) in the 1980s and developed all-new submarine construction techniques. More recently he built an experimental dry combat submersible (DCS) for the U.S. Navy SEALs.

The submarine has an overall length of 23 meters (75 feet) and a width of 5 meters (16 feet). It can dive to 200 meters (650 feet) and reach speeds of 12 knots. The crew of 6 can be accompanied by a further 6 passengers, typically special forces combat swimmers. These can lock out of the submarine through a special hatch to conduct covert operations.

While relatively short, its fatter beam gives it an overall size comparable to a typical 30 meter (100 foot) submarine. Comparable types, in size terms, include the Iranian Ghadir Class (actually the North Korean Yono design) and the Italian built Cos.Mo.S MG-110.

The M23 design is comparatively heavily armed, with two torpedo tubes housed under the casing. These can house standard 553mm (21 inch) heavyweight torpedoes. The submarine can also carry Murena smart sea mines and launch loitering munitions.

Source: Naval News