In a world first, the Hamburg Port Authority, Deutsche Telekom, and Nokia are testing new aspects of the 5G standard using various applications in real-world industrial conditions at the Port of Hamburg in Germany. Covering around 8,000 hectares, the Port back in January became a testing ground for reviewing innovative technology and its suitability for rollout in an industrial environment. The field test is being carried out as part of the EU-funded 5G-MoNArch project in Hamburg and is set to run for two years. The goal is to establish a basis for defining further aspects of the 5G standard.

Three case studies using real-life applications demonstrate the reliability of the new standard. In the first, partners have installed sensors on ships belonging to HPA’s subsidiary, Flotte Hamburg GmbH & Co. KG. These sensors transmit movement and environmental data in real time from across large swathes of the Port. In another example, a traffic light has been linked to the mobile network and can be operated remotely by the HPA control center to control traffic as it flows through the Port. Trucks, for example, are guided quickly and safely around the site. In the third example, the new standard makes high data volumes available quickly outside of existing networks, transmitting 3D data to an augmented reality application. Smart glasses use the information to show wearers building data relating to future or former structures in a real environment. In future, this technology will help engineers to monitor or optimize construction planning directly on site at the Port.

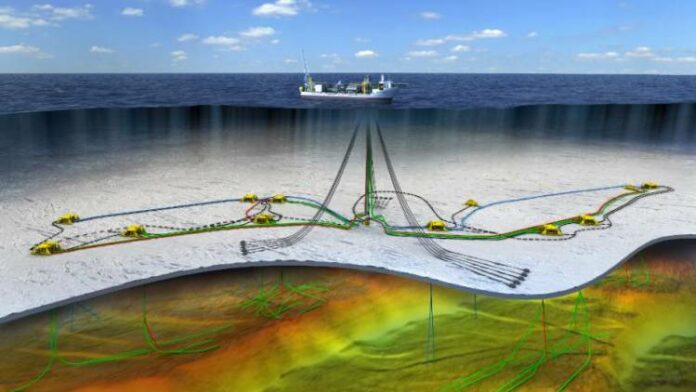

The aim of the Port of Hamburg project is to gain evidence that complex mobile applications with many different requirements can work reliably over one single network. Take particularly high data rates or a high volume of sensors, for example. In order to cope with these demands, the mobile network in the test environment is split into special virtual networks known as network slices. Each slice supports a specific requirement. The result? Separate virtual networks that can be used for managing the traffic light system or transmitting environmental data, to name just two. The new architecture is the first of its kind to allow networks to be adapted dynamically and flexibly to the demands of a broad spectrum of applications. 5G really is the intelligent network of the future.

“The test bed has given us a glimpse of the huge potential that 5G and, in particular, network slicing will offer,” says Jens Meier, CEO of HPA. “I believe the new standard will form the basis for solving tricky industry challenges and is the last push we need to make a breakthrough in terms of digitalization. I’m proud that the City of Hamburg and the Port of Hamburg are among the first to benefit from this technology.”

Antje Williams, Executive Program Manager 5G at Deutsche Telekom, said: “This EU project is an amazing opportunity to test out key aspects of the new 5G technology together with our customer HPA and develop it in line with the customer’s needs. Not only are the findings from the project useful for the future standardization of 5G, but they also enable us to come up with new and innovative solutions for industry.”

“Ports in general need to run smoothly and incredibly efficiently. At the Port of Hamburg, we have demonstrated that 5G can play a big role in this regard. The testing ground is delivering invaluable hands-on experience and data that will help us when implementing future Smart Port concepts using 5G communication networks and technologies like network slicing,” adds Marc Rouanne, head of Mobile Networks at Nokia.

The technological basis for the testing ground is provided by a transmitter installed at a height of over 150 meters on Hamburg’s television tower in January 2018. The stability of the mobile signal is monitored and verified by numerous measurement runs on land and the Elbe river. Industrial applications require a telecommunications network that is reliable and highly secure. Equally so, it must be able to support a large spectrum of applications. As the findings from the 5G testing ground have now demonstrated in practice, network slicing is the way forward.

5G, the next-generation communications standard, carries huge potential for use in an industrial environment. The Hamburg Port Authority (HPA), Deutsche Telekom, and Nokia are happy with developments at the 5G testing ground since it went into operation.

Background to 5G MoNArch

5G is a completely new network concept that integrates fixed-line and mobile communications. However, it’s not solely about making bandwidths ever larger or speeds ever faster. 5G will be used for many diverse applications with very different requirements in terms of speed, response time, security, and capacity. It will play a key role in new applications emerging from the Internet of Things and Industry 4.0. Both the manufacturing and logistics industries in particular can benefit enormously from 5G mobile communications.

The 5G trial at the Port of Hamburg is part of a two-year research project entitled 5G MoNArch (5G Mobile Network Architecture for diverse services, use cases, and applications in 5G and beyond). 5G MoNArch aims to implement concepts for 5G mobile communications architecture in practice. Findings from the deployment of 5G network slicing in a real-world test environment are used to review and improve the underlying concepts.

While the focus in Hamburg is on integrating 5G into transportation and infrastructure management systems, a second testing ground in Turin is looking at multimedia applications. The Horizon 2020 EU Framework Programme for Research and Innovation is funding the 5G MoNArch project as part of phase II of the 5G Infrastructure Public Private Partnership (5G PPP).

Source:hellenicshippingnews