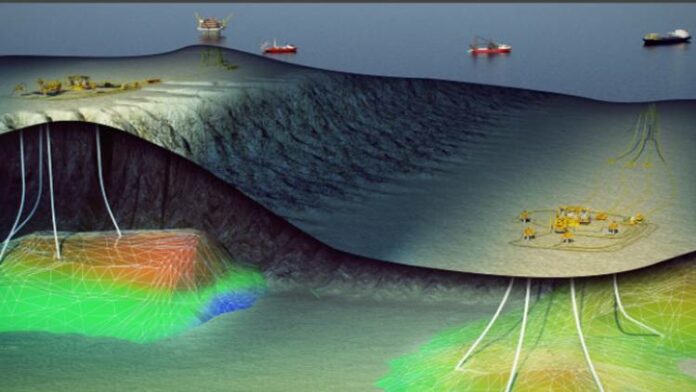

Since 2011, Equinor has cut CO2 emissions from its logistical operations for the Norwegian continental shelf (NCS) by 600,000 tonnes. The company now aims to halve emissions in the NCS supply chain by 2030.

On Friday 18 January, NorSea will open a shore-to-ship power supply station at the Dusavik supply base by Stavanger. Shore-to-ship power supply is one of the measures to reduce emissions in logistics.

Since 2011, overall emissions have been reduced by 37%, while emissions adjusted for reduced activity have been reduced by 26%. Now Equinor aspires to reduce its emissions in the NCS supply chain from 26% to 50% by 2030, based on 2011 level.

Currently, more and more shipowners with supply vessels in the Equinor portfolio are prepared for hybrid battery operation and shore power supply.

A key financial contributor for shipowners aiming to adapt their vessels to hybrid battery operation and shore power supply, the NOX fund provides financial support based on how much the systems are being used up to a ceiling.

"We have an ambition of moving all vessels on long-term contract with us to shore power, because we have seen that it is an efficient tool for reducing emissions. We note that shipowners, crews, base companies and authorities are strongly committed and willing to prepare for operation and infrastructure that will help reduce emissions."

Philippe F. Mathieu, head of Equinor’s joint operations support cluster, stated.

In addition, shore-to-ship power supply stations have been installed at the supply bases at Mongstad in Hordaland, Florø in Sogn og Fjordane, Kristiansund in Møre og Romsdal and Hammerfest in Finnmark during 2018.

Source:safety4sea