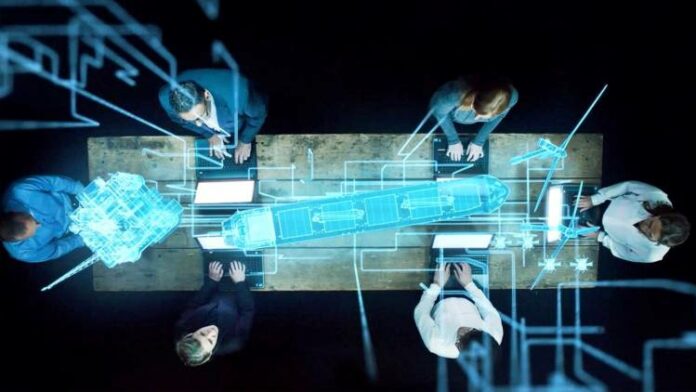

As digitalization is becoming an integral part of the shipping industry, more and more operators can benefit from its use. An interesting new technology that aspires to move maritime forward, is the digital twin concept. Digital twins provide a virtual model of a physical ship, producing valuable insights from data. So, what exactly is a digital twin ship?

Brief history of the digital twin concept

Michael Grieves, from the University of Michigan, was the first to write about this technology, using the term ‘digital twin’, back in 2002. However, NASA was using pairing technology, the predecessor of digital twin, back at the beginning of space exploration.

NASA wanted to find a way to operate, or repair systems when they are not near them. Especially, when the Apollo 13 disaster took place, it was this technology that enabled engineers and astronauts to see how they could rescue the mission.

Today, NASA uses digital twins to test and build its equipment in a virtual environment, according to John Vickers, NASA’s leading manufacturing expert and manager of NASA’s National Center for Advanced Manufacturing.

When they are sure that a system performs perfectly to the necessary requirements, only then they proceed to manufacture it. After that, the physical asset is connected with a digital twin to enable better inspection.

What is a digital twin?

A digital twin is a digital replica of a living or non-living physical entity. By combining the physical and the virtual world, data is provided enabling the virtual entity to exist at the same time with the physical entity.

Specifically, a digital twin digitally replicates physical assets that can be used for various purposes. This digital representation provides the elements and the dynamics of how an Internet of Things (IoT) device operates and lives throughout its life cycle.

The fact that these processes are presented digitally, means that there is no need to arrange for a physical test cycle.

Today, there are estimates that the digital twin concept will be widely used in the near future. In fact, by 2021, half of large industrial companies will use digital twins, achieving 10% improvement and effectiveness.

How does the digital twin works

A digital twin basically links the physical and digital world.

At first, smart components use sensors to collect data about real-time status, working condition, or position that are incorporated within a physical item.

These components are connected to a cloud-based system that receives and analyzes all the data the sensors monitor.

The technology then provides lessons learned, while opportunities are presented within the virtual environment. These opportunities can then be applied to the physical world.

Better evaluation of ship’s performance

What is very important is the fact that a digital twin can simulate how the ship will perform without needing to test it in the real world. This concept can also allow access to every bit of information on a ship, from engine performance to hull integrity, available at a glance throughout the full lifetime of the vessel.

The use of a virtual model such as the digital twin during operation, provides a great opportunity to visualize all important components, carry out analyses, and improve the operation on the ship’s structural and functional components.

In addition, using the digital twin, operators can plan for a more efficient inspection and maintenance. This can also lead to an extension of the ship's lifetime, as preventive measures will be taken to avoid damages.

Specifically, operators can create visual models of the ship and its underlying systems, such as engine spaces and pumps, and continuously record its fuel consumption, distributed on sources of energy, such as engines, boilers and batteries.

Other outcomes could be simulation and analytical models that are developed to acquire the optimum fuel consumption for a particular voyage with a specific cargo, by including external factors such as wind, current and weather conditions.

Commenting about the advantages of digital twins, Gaute Storhaug, Principal Specialist, DNV GL, said :"The increased transparency and control that the digital twin provides can even result in a competitive advantage by improving predictability."

At a glance, some areas for potential improvements that can be calculated by a digital twin are:

- Optimal operation of machinery systems.

- Optimal retrofit of batteries, more efficient thrusters, bulb etc.

- Performing hull or propeller cleaning.

- Verify ship performance on a detailed level. Visualise the effect of design choices and changes.

- Benchmarking performance towards other vessels in the fleet.

Of course, as many actors are involved in the shipping industry, the digital twin can benefit the wider sector:

- For ship owners, digital twins will provide a tool for visualisation of ship and subsystems, qualification and analytics of operational data, optimisation of ship performance, improved internal and external communication, safe handling of increased levels of autonomy and safe decommissioning.

- For equipment manufacturers, the digital twin will provide a tool to facilitate system integration, demonstrate technology performance, perform system quality assurance and promote additional services for monitoring and maintenance.

- For authorities, the digital twin will offer a systematic framework that can be set up with applications to feed live information and generate required reports from each ship. This can ensure higher quality reporting on critical issues without putting extra burdens on crew.

- For universities, the digital twin offers a new platform on which to increase system understanding and facilitate knowledge exchange enhancing research and development and education in a range of technological disciplines.

- For maritime academies, the digital twin can act as a platform for training that can increase each candidate’s understanding of the whole ship and train them in systems thinking to see the integrated consequences of actions taken.

- Digital twins will require specialised consultancy services. Their role will be to accelerate efficient generation of the digital twin concept, e.g. with regard to state-of-the art requirements and standards for model exchange and handling of large scale data.

Early adopters of digital twins

The concept is currently taking off. In fact, the Danish Maritime Authority has focused on 'Digital Twin' concept for shipping. As Mogens Schrøder Bech, Senior Consultant on R&D at the Danish Maritime Authority, said: "The potential of the digital twin is huge because it is possible to make a number of decisions on optimisation digitally rather than by means of physical tests. And this potential will increase along with the development of digital tools."

Moreover, during 2017, Rolls-Royce Marine, The Norwegian University of Technology Science (NTNU), SINTEF Ocean, and DNV GL signed a memorandum of understanding (MoU), to create a digital platform, for ships to use. Namely, a prototype of the Open Simulation Platform (OSP) is running with a simulated ship and a DP system, performing a dynamic positioning operation. This prototype uses cloud technology, facilitating teams to enhance system design and vessel performance, verify correct handling of failures within the control system of the vessel’s automated positioning system, and verify system changes and the operational impact.

MPA Singapore has also jumped on the digital twin train. MPA signed an MoU with Keppel Offshore & Marine and the Technology Centre for Offshore and Marine, Singapore (TCOMS), to jointly develop autonomous vessels for a variety of operations.

Under the deal, a project will develop a Digital Twin of a tug which will simulate vessel behaviour to help optimise the vessel operations using data analytics and visualisation tools. TCOMS will provide expertise in coupled physical-numerical modelling and simulation to evolve solutions that improve on the predictability and control of the behaviour and response of the vessel.

There is no doubt that the digital twin is the future. Being able to predict potential dangers and create the optimum design, will enhance safety and operation greatly. With the element of the unknown significantly limited, the digital twin concept can help the shipping industry make better use of digitalization, and move to a new era.

Source:safety4sea