Thanks to Bakker Sliedrecht, the new trailing suction hopper dredger Schenge from the Goes based Faasse Groep will become energy-efficient. The electrical drive specialist supplies and installs a shaft generator on the main engine, which generates the electricity for the entire dredging installation. As a result, the ship works more efficiently, needs less maintenance and has an optimized lay-out.

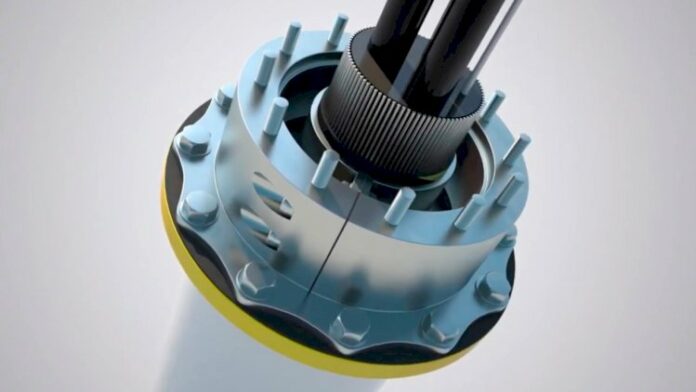

Early this year, Faasse bought the freighter MS Mandeo in order to be converted into the trailing suction hopper dredger Schenge. After its completion in 2020, the vessel will be deployed for sand extraction in the North Sea. The Schenge has a hopper capacity of approximately 2600 m3, divided over two holds so that it can carry two types of product. For the electric drive of the dredging installation and jet pumps, a shaft generator with matching frequency drive from Bakker Sliedrecht is added, which is connected to the existing main engine by means of a new PTO shaft. The vessel has an adjustable propeller (CPP). Because the main engine runs at a low load for propulsion during dredging, this power can be used for the electrical dredging installation.

As a result, the trailing suction hopper dredger does not require any auxiliary diesel generators. This saves a lot of fuel, space, piping, and maintenance.

Senior Electrical System Designer Marcel Bakker and Sales Engineer Wim Verlek of Bakker Sliedrecht, said:

“We use the power that the main engine does not need during dredging. That makes the ship much more efficient and also ensures energy-efficient operations. Moreover, this solution saves a lot of space and allows a flexible and optimized lay-out of the vessel.”

During the conversion of the ship, Bakker also supervises the installation on board and the commissioning. The crew is also trained in dealing with the frequency drive so that they are familiar with the operation of the systems and the supplied manuals. Bakker Sliedrecht has applied this type of electrical installation more often, but mainly on larger dredgers. The Schenge is the first ship of Faasse in this category to be equipped with it.

The Faasse Groep produces three million tonnes of sand annually for the concrete industry, infrastructure, sports fields and beach spraying. The sand is extracted off the Dutch and Belgian coast and transferred to inland barges. The 140-year-old Zeeland family company invests continuously in sustainability and innovation to keep the fleet up-to-date.

Bakker and Verlek said:

“Faasse came to us because they expect us to have some expertise in this area. We know how to handle quality and sustainability and are able to deliver this kind of advanced electrical solutions.”