The Department for Energy Security and Net Zero confirmed the Floating Offshore Wind Manufacturing Investment Scheme (FLOWMIS) funding for the Invergordon-based Trust Port’s ‘Phase 5’ expansion, which aims to establish the UK’s first custom-built integration hub for floating offshore windfarm construction.

The award paves the way for Port of Cromarty Firth to secure match-funding from banks and/or other investors, and to award a pre-construction contract to kick off work on Phase 5, which must be completed in 2027 to be ready for the first commercial-scale floating wind projects.

The expansion project is expected to create 170-320 jobs in the construction phase. When complete, it will provide the larger facilities needed for the construction, installation and operational support to offshore and floating offshore wind – a vital component of regional jobs and growth, national energy security (and reduction of energy bills), and to Scotland and the UK achieving their Net Zero obligations.

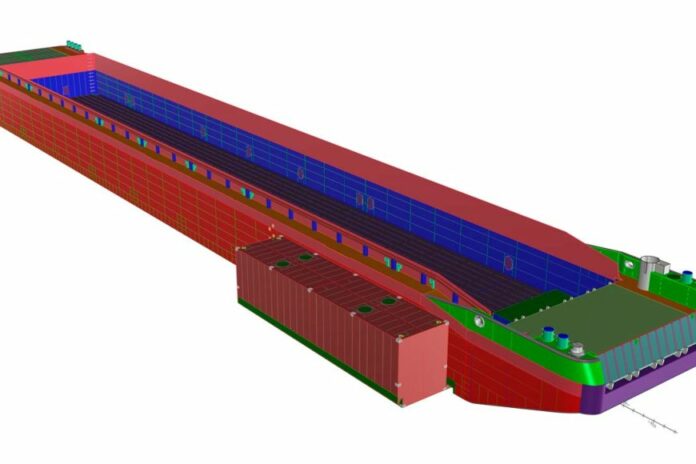

The Port’s deep, sheltered waters are perfectly suited to accommodating the large ships which will deliver the major components required for offshore wind, such as the towers, blades, steel or concrete floating foundations. These will be manufactured around the UK and further afield. Once received onto the Quay West and new Phase 5 laydown area, the floating turbines will be assembled and pre-commissioned, before being towed to the windfarm site. This is expected to create 280-1000 jobs, depending on the realised design.

The offshore wind project pipeline is one of the UK’s largest opportunities to create economic growth and jobs. FLOWMIS was launched in 2023 as part of the UK Government’s Powering Up Britain plans in order to distribute funding needed to boost larger port infrastructure that enables the delivery of new floating offshore wind farms. Two ports – Port of Cromarty Firth and ABP Port Talbot in Wales – were provisionally awarded the funding in March last year, subject to due diligence and subsidy control.

In the last decade offshore wind turbines have steadily increased in size and moved into deeper water – necessitating the need for larger Port facilities. New floating wind technology provides an opportunity for Scotland and the UK to undertake a greater proportion of the work and associated manufacturing. Funding these two port facilities is a statement of the UK’s intent to position our country as leaders in this sector, and to ensure developers deliver real benefits to the local communities who host these facilities, through jobs and business opportunities.

Alex Campbell, Port of Cromarty Firth Chief Executive, said: “The Port is delighted that FLOWMIS funding has been secured for our ambitious Phase 5 expansion, which is a critical step towards creating the UK’s first custom-built floating offshore wind integration port.

“We believe this confirmation by the Department for Energy, Security and Net Zero shows the faith in our Trust Port status to deliver the jobs and growth locally and nationally, for the benefit of all stakeholders, with any profits generated reinvested back into our infrastructure and development.

“It also recognises the Cromarty Firth’s position among industry and government as the most logical location for a strategic national floating wind hub, due to its sheltered deep waters, proximity to wind farm sites, and skilled local workforce and supply chain, who have huge experience in delivering large energy projects such as the multi-billion-pound Moray West.

“FLOWMIS funding now allows us to finalise the match funding and supporting contractual commitments, and final designs, necessary to make this vision a reality.

“We believe the certainty from this announcement will also unlock further investment in other Ports across the Inverness and Cromarty Firth Green Freeport to boost their complementary plans – for instance the assembly of floating wind foundations.”