Damen Shipyards Group has signed a contract with Forth Ports Limited for an ASD Tug 2312. The signing ceremony took place in Tilbury Docks, UK on 26th February.

Representing Damen was Area Director Frank de Lange, while Forth Ports was represented by COO Stuart Wallace. The new vessel will operate as part of the Forth Estuary Towage operation, conducting towage work at various Forth Ports locations as well as providing towage services to other external customers in Scotland.

Forth Ports has a range of existing operations in the Forth and Tay Estuaries that will benefit from the acquisition of this new vessel, however, the new vessel will also provide opportunities to service new emerging markets such as decommissioning and offshore wind. The ASD 2312 is well suited to operating in such an environment with such vessels; compact, but, with 70 tonnes bollard pull, extremely powerful.

She’s manoeuvrable too – thanks to her twin fin skeg and dual azimuth thrusters. The ASD Tug 2312 is a state-of-the-art vessel, one of Damen’s next generation tugs. The evolved character of the vessel is clearly visible in its safety features. The wheelhouse, for example, offers 86% window coverage, using impact resistant safety glass.

Meanwhile, the deck is obstacle free, reducing tripping hazards. The winch is located under the superstructure, which not only frees up space, but also facilitates towing operations both forward and aft. The tug is prepared for the future, being IMO Tierr III ready. Emissions are further reduced thanks to the tug’s smooth rounded bilge, an efficient profile that cuts fuel consumption. Damen has prepared a NOx Reduction System that can be applied to IMO Tier III ready vessels at any stage for full compliance.

Meanwhile, smart layouts and compliance with MLC 20006 crew accommodation and comfort regulations ensure the six-person crew are on top form at all times.

As a result of Damen’s philosophy of standardised shipbuilding, the ASD Tug 2312 was already under construction when Forth Ports placed their order with Damen, ensuring rapid delivery of the vessel.

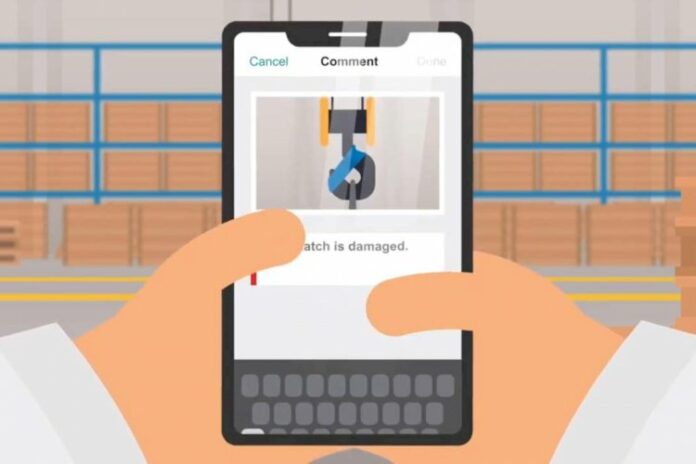

While a standard platform, like all vessels in Damen’s portfolio, the ASD Tug 2312 is customisable via modular options. Forth Ports has selected a number of options for its vessel, including remote monitoring. This, ultimately, can significantly lower the total cost of ownership of the vessel. Amongst other things it provides feedback on performance so that sailing can be optimally efficient. It also informs whenever a part or component needs replacing, so that preventative maintenance can be carried out in order to maximise vessel uptime.

Furthermore, Damen will outfit Forth Ports’ ASD Tug 2312 with CCTV, FiFi capabilities, additional fendering at the bow and a winterisation package, amongst other options.

Damen Sales Manager UK Mike Besijn said:

“We are delighted with this order from Forth Ports. The ASD Tug 2312 is a tug for the future that I am sure will serve them well in the years to come. Forth Ports has carefully evaluated their vessel requirements for both their current and future plans around fleet renewal and we are delighted that they have selected Damen for this replacement tug and we look forward to a long and growing relationship with Forth Ports.”

Alan McPherson, Chief Harbour Master at Forth Ports said:

“We are very pleased to be working with Damen on the delivery of the 2312 to Forth Estuary Towage as we replace older tonnage and significantly increase our towage fleet capability. The team at Damen have worked closely with us to deliver a very capable vessel for the operations we undertake and our staff are looking forward to this type of tug within our fleet. I look forward to building our relationship with Damen in the coming years.”

As Forth Ports required their new tug to be operational as soon as possible, Damen Marine Services (DMS) stepped into to assist. While the new ASD Tug 2312 is under construction, DMS is providing ASD Tug 2811 Pioneer to operate with Forth Ports.