SIMEC Atlantis Energy Limited (“Atlantis”), a global developer, owner and operator of sustainable energy projects, has advised that MeyGen Plc (“MeyGen”) has been awarded a £1.545 million grant from the Scottish Government’s Saltire Tidal Energy Challenge Fund to develop a subsea tidal turbine connection hub for the next phase of development of the MeyGen tidal power array, the world’s largest tidal stream power project.

The Saltire Tidal Energy Fund is a £10 million fund supporting the commercial deployment of tidal energy generation in Scottish waters through driving innovation and a reduction in the cost of electricity generated.

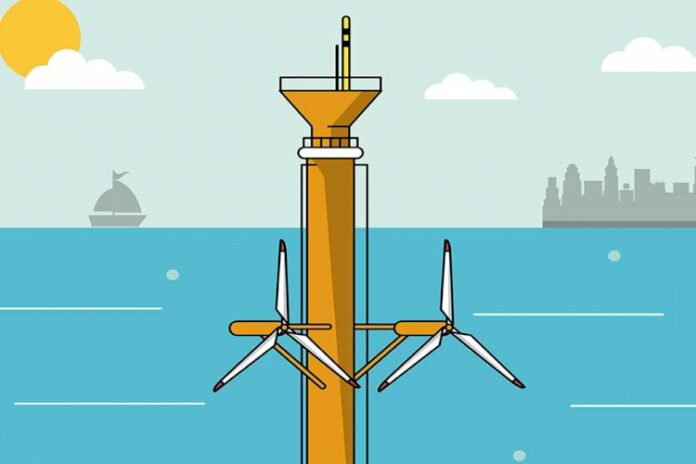

The awarded funding will be used to design, procure, install, connect and commission the subsea hub and associated subsea connection infrastructure, which is a key enabler for future array phases, as it will deliver cost reductions in power production by connecting multiple turbines to a single export cable.

The technology leverages the innovative design of the Atlantis turbine wet mate connection system, which enables rapid and automatic connection and disconnection of power and communication infrastructure offshore without any intervention. This grant award will prove the application and benefits of subsea hub for the global tidal power industry. Once proven, the hub will be made available to project developers to help to achieve cost-competitive commercial deployment across the sector.

As a result of the grant award, the Atlantis’ Turbine and Engineering Services Division (“ATES”) will be awarded a £2.4 million Engineering, Procurement and Construction Contract (“EPC Contract”) for delivery and installation of the subsea hub by the MeyGen project company on the MeyGen project site in the Pentland Firth, Scotland. The subsea hub, which will be assembled and tested in Scotland, will be installed later this year (2020).

Tim Cornelius, CEO of Atlantis, commented:

“We are very grateful and appreciative of the Scottish Government’s continued support for tidal stream energy by awarding this grant to help fund MeyGen’s ongoing expansion. The first of its kind globally, the new subsea hub represents a significant milestone in the cost reduction path that tidal power is currently on and also has exciting application in the floating offshore wind market.

The subsea hub we have designed and developed is a key part of our overall cost reduction strategy for tidal power generation. This hub will also have direct application for other forms of marine energy such as floating offshore wind and wave energy. We are very proud to be taking the lead in realising the full potential of our oceans’ energy, delivering a cleaner energy future.

I would also like to personally thank our dedicated marine energy team for their hard work bringing this project to fruition. The next phase of MeyGen, which will supply ocean energy to a large data centre to be built in Scotland, requires us to deliver cost competitive energy to our future customers and the use of subsea hubs to reduce the number of export cables required to deliver this power from the 40 x 2MW turbines we plan to install is central to our plans. This is a wonderful development for the MeyGen project, our ATES division and the tidal power sector in the UK.“