In an industry milestone, joint venture CSBC-DEME Wind Engineering (CDWE) has initiated the early works contract for the very first floating heavy lift and installation vessel to be built in Taiwan. To be named ‘Green Jade’, the vessel has an exceptionally high transport and load capacity and will be built at CSBC in Taiwan for delivery in 2022 for deployment in the flourishing local offshore wind market.

CDWE, Taiwan’s first offshore wind EPCI contractor, was established in February 2019 by CSBC, the largest shipbuilder in Taiwan, and DEME Offshore.

Both partners have agreed to start up the early works and the ordering of critical packages for their pioneering new asset, ‘Green Jade’. The name symbolises Taiwan’s renowned Yushan, the Jade Mountain. At a dizzying height of 3,952 m above sea level, Jade Mountain is the highest peak in East Asia and gives Taiwan one of the highest elevations of any island in the world. Additionally, the name ‘Green Jade’ reflects this trail-blazing vessel’s contribution to reducing emissions, and its role in bringing clean, green energy to Taiwan’s residents. By choosing such an auspicious name, CDWE wants to highlight our ambitions to develop the offshore wind industry and to successfully ‘scale the summit’ together.

In October last year, CDWE signed Taiwan’s first comprehensive, large-scale Balance of Plant (BOP) Preferred Supplier Agreement with the Hai Long Offshore Wind Project. This marks an important step in realising industry compliance with the ‘Industrial Relevance Plan Goals’ that the Taiwan Government has mandated in the offshore wind industry.

Swiftly following on from this first success, CDWE has signed two contracts with Zhong Neng Wind Power Corporation Preparatory Office for the 300MW Zhong Neng offshore wind farm project. The contracts comprise the transportation and installation of foundations, as well as a Preferred Bidder Agreement for the transportation and installation of the wind turbines.

‘Green Jade’ will be deployed on both projects. CDWE is committed to meeting localisation requirements and assisting with the development of the offshore wind industry, and a successful and sustainable supply chain in Taiwan, optimising local materials and skills.

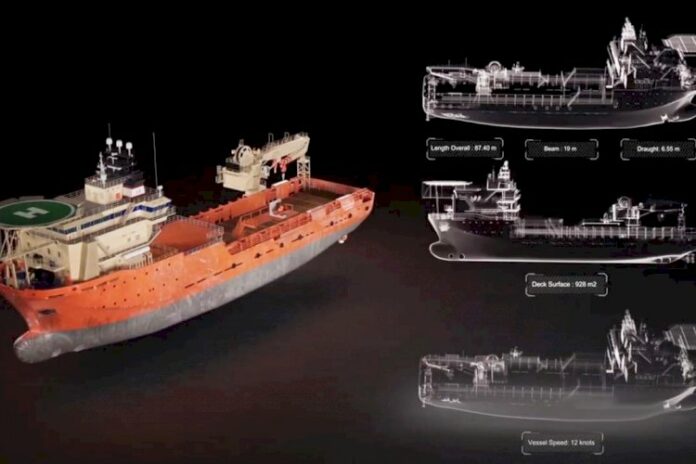

‘Green Jade’ will feature a high-tech, 4000-tonne capacity crane and DP3 capability. The vessel’s deck space has been maximised, enabling this unique asset to transport a multitude of the heaviest monopiles, jackets, wind turbine components and structures in a single shipment. With this exceptional combination of high load and lifting capacity, ‘Green Jade’ can transport and install the next generation of foundations and giant multi-megawatt wind turbines in the most cost-effective way. At 216.5 metres long, ‘Green Jade’ can comfortably accommodate a crew of up to 160 people.

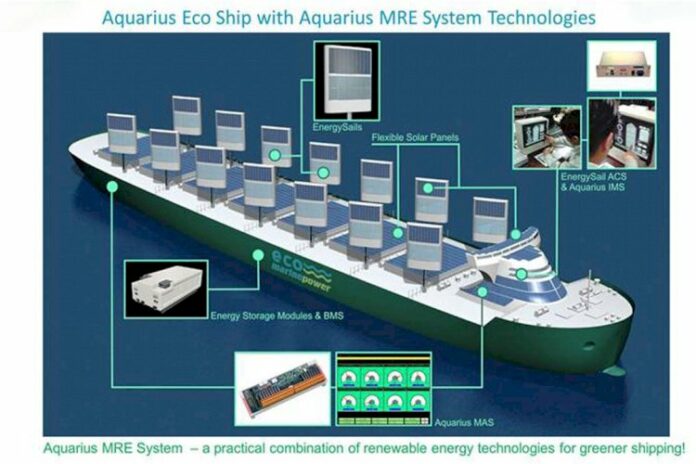

Environmental considerations are an important element of the vessel design. ‘Green Jade’ has dual fuel engines and will have a Green Passport and Clean Design notation. ‘Green Jade’ will also have other environmental innovations on board, including a waste heat recovery system that converts heat from the exhaust gases and cooling water to electrical energy, in addition to various other fuel-saving measures.

This is a historic moment in Taiwan’s offshore wind development and indeed for the Taiwanese shipbuilding sector, as this dedicated offshore installation vessel is the first of its kind to be built in Taiwan for the local renewables market.

Hai Long EPCI Director, Felipe Montero, enthused:

“Hai Long and CDWE started this partnership by signing a MOU on March 9th 2018 before the allocation round took place. The BOP conditional contract was signed in October 2019, covering EPCI for the foundations, inter-array cables & export cables and the T&I of the turbines, giving CDWE their biggest scope and contract so far. This also allows them to participate from the beginning of the development until the end of the construction. Hai Long is delighted to see CDWE taking steps to construct the first offshore installation vessel in Taiwan. We are very proud of having contributed to this milestone which demonstrates Hai Long’s commitment to supporting the development of the local supply chain. Hai Long will continue to collaborate with CDWE on cultivating a sustainable local supply chain, while exploring more opportunities in supporting the localisation policy.”

Frank Rijnja, Procurement Director of the CIP-CSC co-developed Zhong Neng Offshore Wind Project, said:

“Zhong Neng awarded the Foundation T&I scope for the 300MW Zhong Neng Offshore Wind Farm to CDWE in December 2019. One of the reasons was to support the government’s localisation policy and to provide CDWE with confidence, enabling the company to take the decision to invest in a locally built and state-of-the-art installation vessel. We believe Zhong Neng’s firm order to CDWE will create high value jobs for Taiwan’s shipbuilding industry. This cooperation between Zhong Neng and CDWE resulted in the successful submission and IDB approval of Zhong Neng’s Localisation Proposal.”

Robert Tseng, Chairman of CDWE, comments:

“The establishment of CDWE is a perfect combination of DEME’s unrivalled strength in the offshore wind power segment and CSBC’s leading position in shipbuilding, vessel operation and foundation fabrication in Taiwan’s offshore wind farm development. CDWE, the localised Taiwanese offshore engineering company has demonstrated its reliability and capability to the clients by winning various iconic T&I or BOP projects, and by playing a key role in bringing Taiwan’s offshore engineering capabilities to a higher level. This key role and strength of CDWE will be further enhanced by investing in this Locally built/Locally owned/Locally operated Main Installation Vessel, and I do believe ‘Green Jade’ will shape a promising and flourishing future for Taiwan’s offshore wind business.”

Hugo Bouvy, Managing Director DEME Offshore,comments:

“We are very excited to initiate the early works of the first floating offshore installation vessel in Taiwan. With ‘Green Jade’ we will be uniquely positioned to meet the requirements of the Taiwanese offshore wind market, and to be an integral part in the country’s offshore wind development ambitions. Taiwan is a pioneering and dynamic renewables market with plenty of opportunities for CDWE, a leading company in the global offshore wind industry. Our commitment to this market is clear to see from the substantial investment in ‘Green Jade’ and the local presence of our highly-skilled offshore wind professionals. The Hai Long and Zhong Neng Projects have played an integral part in our decision to invest in an installation vessel. They have offered us an extensive scope of works beyond the Government’s Bureau of Energy’s localisation requirements, and are our anchor projects until Round 3 projects commence, giving confidence to our internal stakeholders and lenders that this vessel will have a strong pipeline of work and can be integral to Taiwan’s offshore wind development ambitions.”