Maersk’s Asia-Northern Europe ocean-rail service, previously offered on monthly basis in west-bound direction only, will now be provided fortnightly both export from Asia to Europe and return from Europe to Asia.

This is expected to help many customers who are currently facing difficulties with their imports/export logistics, due to COVID-19. Maersk recently announced that its combined Ocean and Rail service, AE19, will now be offered on a regular basis for both directions through close cooperation with Pantos Logistics. Customers would practically see the benefits of weekly service combining Maersk’s fortnightly AE19 service and Pantos Logistics.

AE19 managed to successfully position itself as an attractive alternative to Ocean and Rail services for customers who are currently experiencing problems with transporting their cargo, such as blank sailing, lack of containers, and sky-rocketing air rates, due to COVID-19.

The entire journey, starting from Busan to Vostochy in a vessel, followed by Vostochy to St. Petersburg by rail, takes a mere 16 days. In this way, AE19 can offer highly competitive transit times for customers. Following a successful pilot launch of the West-bound service last August, the recent launch of the bi-directional service has also been highly successful. Transit times from South Korea and Japan to Northern Europe have been reduced to 23-32 days from the previously 52-57 days through intermodal transportation. Jason Park, Head of Maersk Korea, adds:

“Frequent cancellations and congestions in ports and airports around the world due to COVID-19 have made the usual Ocean and Air services less attractive for customers. Evidently, AE19’s volumes have increased by approximately 30% compared to pre-COVID-19, compensating for the reduced demand for our other services.”

The transition to a fortnightly service is proving to have a positive impact in attracting more customers for Maersk. As regularity, timeliness, and cost-friendliness are all equally important factors to consider for many customers, AE19 gains its competitiveness by offering lower rates than Air, while still ensuring a faster transit time compared to Ocean for their high-value, large-volume cargos.

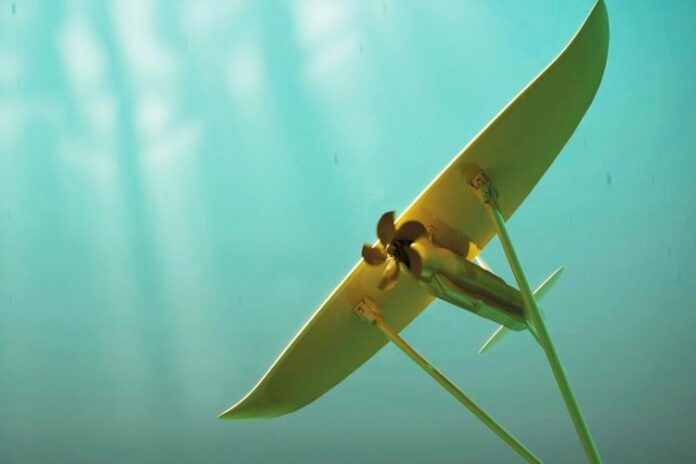

Photo: Maersk

For customers who are used to using either only Ocean or only Air services originally, AE19 now offers an option to diversify their transportation routes as the pandemic continues. Moreover, because the rail service only operates within Russia, customers can also avoid border congestions that are typically associated with intercontinental transportation within the route and expect a more seamless service overall. Key Client Manager, Sung Don Yang said:

“AE19 service attracts many customers by allowing them to manage transportation risk, providing cost competitiveness and connecting various origins and destinations.”

The possibility to now transport dangerous cargo through rail, and not only through ocean, demonstrates one of Maersk’s many efforts coming into fruition. Automotive batteries, one of Maersk’s key transported products, are classified as dangerous cargo. Up until now, this product would not have been permitted on the TSR (Trans-Siberian Railway), due to its dangerous cargo classification. However, through close cooperation with Russian Railways and Modul LLC as Rail transport providers of AE19, Maersk is leading dangerous cargo transportation by TSR. For a railway company that places safety as its utmost priority, this news comes to show that Maersk’s long-established expertise in dangerous cargo transportation has been fully appreciated. Pantos Rail-Transport Business division director, Ha Hyeong Lee, said:

“We expect this to become an important milestone in bringing Eurasian international railing service to the next level – by combining rail transportation services with Maersk’s current capabilities as a global shipping company.”

Maersk plans to further increase volume by targeting customer segments dealing with high-value and/or lead-time-sensitive cargos, such as Automotive, Electric, and Facilities sectors. Park emphasizes that:

“Simplified supply chains pose significant risks to businesses in case of a global pandemic like COVID-19. The intermodal AE19 service offers a compelling alternative to the long transit times in Ocean transportation and the expensive rates in Air transportation”.