Chinese e-commerce and technology group Alibaba has signed up to the International Port Community Systems Association’s (IPCSA) ground-breaking Blockchain Bill of Lading initiative and embarked on a new blockchain project in the organisations’ joint Logistics Visibility Task Force.

The joint work is aiming at standardisation and proof-of-concept (POC) of blockchain application in logistics and e-commerce.

The IPCSA Blockchain Bill of Lading initiative is being led by an IPCSA member, Israel Ports Company, which operates the Israeli Ports Community System (IPCS). This year, Israel Ports Company ran a number of successful pilots using Blockchain technology for transferring electronic Bills of Lading. Some pilots involved the shipment of a cargo via ZIM Shipping Company from Israel to Ukraine, where IPCSA member PPL 33-35 operates that country’s Port Community System. The exporter was Adama Israel, with shipments to Adama Ukraine, with the help of customs agents Damco (Israel) and Rem-trans (Ukraine).

A Bill of Lading was electronically issued by the shipping company and transferred to the exporter and then to the importer in Ukraine/Spain. The system provides information as to which party holds the electronic Bill of Lading at any time, together with the logistics status of the cargo.

Ms Zhu (Judy) Hongu, Head of the Standardization Department of Alibaba Group, said:

“Alibaba and IPCSA have been working closely together for the past two years. In October 2018, in collaboration with LOGINK (China’s national logistics information shared network), we set up a global intelligent logistics network, named the Logistics Visibility Task Force. In its work to develop global smart supply chains, the Task Force has focused on the development of track and trace solutions and the use of ISO standards. Following on from this work, Alibaba has signed up to the IPCSA Blockchain Bill of Lading initiative, effectively making this a second workstream of the Task Force.”

Mr Sun Tengda, General Director of LOGINK, said:

“Working with Alibaba and IPCSA together, Logistics Visibility Task Force endeavoured to solve the problems in cross border logistics information sharing, trace and track service was the first breakthrough, and the ISO standards we are working on is also part of the mission. Now, with the technical advantage of Blockchain, we are looking forward to explore an innovative route to establish this globally trusted network together.”

Ms Gu Xuemei, Alibaba Cainiao Network CTO, said:

“The use of Blockchain in transferring an electronic Bill of Lading is expected to deliver significant savings in time and money to all participants in the supply chain, while maintaining a high level of information security and preventing forgeries. In addition, Alibaba Cainiao Network hopes to cooperate with industry chain partners to build global blockchain application standards for logistics and e-commerce.”

Richard Morton, secretary general of IPCSA, said:

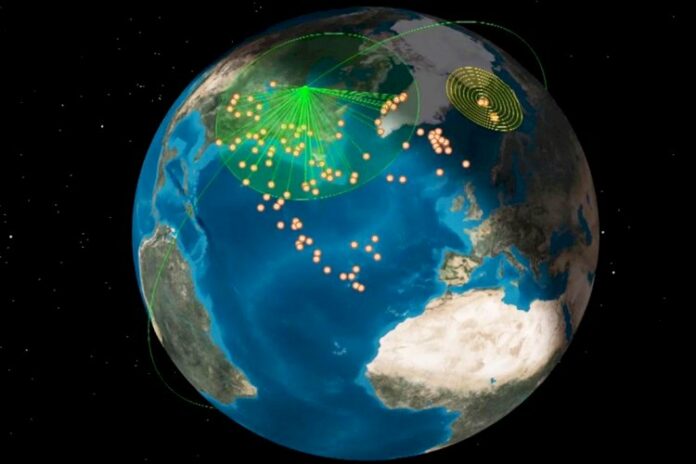

“There are numerous strong reasons for using Blockchain technology for Bills of Lading. Blockchain is transferring an asset and there is huge value in linking the consignment to the information that Port Community Systems hold. This can match the Bill of Lading to any ‘event’ during the movement of the cargo – for example, that the cargo has been loaded on the ship, arrived at port, been unloaded, been cleared by customs, or exited the gate. By matching these events to the Bill of Lading, the solution gives much-needed information and flexibility.

There are multiple parties involved in this process – shippers, shipping lines, importers, banks, forwarders, agents, and so on. By matching information in this way, nodes can be added to the Blockchain relevant to specific partners.

Standardised and structured data is the key to making this work. We recognise that this is a journey. Getting people to use structured data – especially small and medium-sized companies – is a challenge. The IPCSA Bill of Lading will also accept adding PDF and JPG documents in the first version, but ultimately it will be entirely based on Blockchain structured data.”

IPCSA also welcomes the recent Digital Container Shipping Association (DCSA) initiative to help standardise the Bill of Lading, which will help in the acceptance of an eBill of Lading.