thyssenkrupp Marine Systems, Germany’s number three defence company and world market leader in conventional submarines, today presented the results of a pioneering research project on the feasibility, usability, construction and operation of large modular underwater vehicles.

The focus was on the MUM project “Modifiable Underwater Mothership”, which is funded by the Federal Ministry for Economic Affairs and Energy and, designed in collaboration by industry and science since 2017, is intended to achieve market readiness in the upcoming years.

The presentation was part of the “Maritime Research Programme” whereby the Federal Ministry for Economic Affairs and Energy supports the development of innovative maritime technologies.

Norbert Brackmann, German government coordinator for the maritime industry, said:

“The MUM project fits in very well with our aspiration to technological leadership. The project results show that individual commitment, teamwork, creativity and German engineering skills are an excellent combination for maintaining our technological lead in future markets. Given the challenging economic situation triggered by the Covid-19 pandemic, innovations and the further development of high-tech will pave the way to a successful future. Therefore, we have included provisions in the recently adopted economic stimulus package to provide additional funds for supporting innovation and the Maritime Research Programme.”

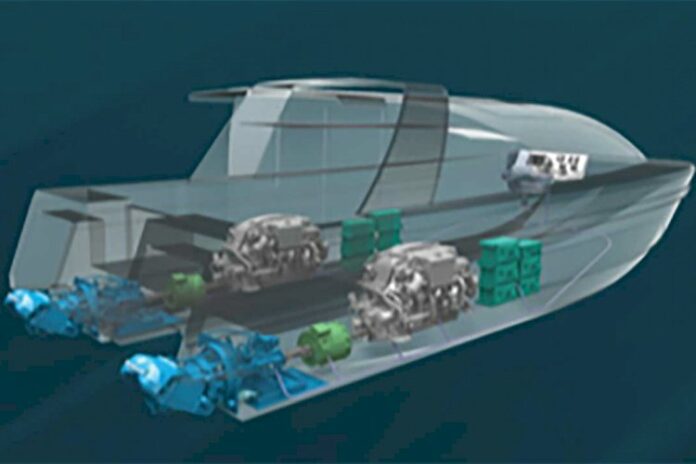

MUM is a modular unmanned underwater system for various applications in the civil maritime industry. Examples include the transport and deployment of payloads, applications in the offshore wind and oil & gas industries as well as the exploration of sea areas with difficult access, such as the Arctic ice regions. In order to meet these requirements, a modular structure is envisaged. The system will use electrical power as the main energy source, by implementing a state-of-the-art, emission-free fuel cell. Where necessary, the power supply system is supported by a safe and reliable Li-ion battery module. Independent of wind and weather, MUM can operate 24/7, 365 days a year.

Dr. Rolf Wirtz, CEO of thyssenkrupp Marine Systems, said:

“We are the only systems supplier in Germany to offer high-tech solutions for the future. The MUM project will benefit from our many years of expertise in fuel cell and battery technology, underwater vehicles as well as maritime sensors and autonomy software. Our project partners from science and industry complement us to an extraordinary degree!”

MUM is to set the new standard for unmanned underwater operations by 2024. Together with the project partners ATLAS ELEKTRONIK, EvoLogics, University of Rostock, TU Berlin, Fraunhofer Institute, German Aerospace Center the Institute for the Protection of Maritime Structures, thyssenkrupp Marine Systems will apply for funding for a MUM large-scale demonstrator as part of the Economic Ministry’s Maritime Research Programme.