The Ocean Tracking Network (OTN), a global aquatic research, data management and partnership platform headquartered at Dalhousie University in Canada, has upgraded their remotely operated vehicle to a 1000-metre rated Saab Seaeye Falcon DR.

Chosen in a competitive bid process, the Falcon was selected as the most powerful and capable ROV of its size, class and depth rating.

Greater depth capability of the Falcon DR extends the potential for maintenance and recovery of lost tracking equipment, lends itself to oceanographic and biological surveying, and expands opportunities for OTN’s research into deep-water habitats.

OTN Executive Director, Dr. Fred Whoriskey, says:

“The Falcon is compact, easily mobilized and versatile, making it attractive to potential partners who are keen to share the vehicle for joint venture research, monitoring and recovery projects.”

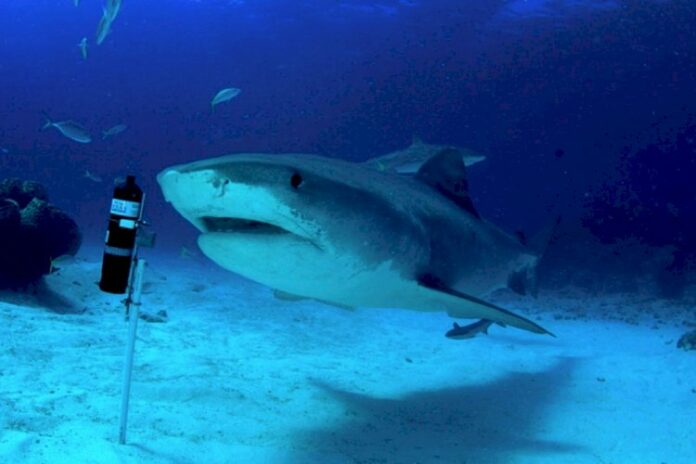

With its high-definition colour camera and built-in tools — including an arm for non-invasive sample collection — the ROV will provide new insights on aquatic animals by offering a new, safer, and less intrusive way to study them underwater.

OTN’s Falcon also comes with an ultra-short baseline acoustic tracking system, a Tritech multi-beam sonar, a Kongsberg high definition video camera and an associated lighting system, making it a highly versatile platform for the maintenance and recovery of OTN infrastructure equipment and providing high quality video for scientific and communications purposes.

OTN has more than 2,000 acoustic tracking stations deployed across five oceans, spanning seven continents, and in freshwater systems that serve as highways to the ocean for species that migrate between fresh and salt waters.

Worldwide, the Falcon can be sent to find stranded stations that have shifted from their coordinates for a variety of reasons, saving the loss of valuable equipment and data.

Just a metre long, with five powerful thrusters and intelligent control, the Falcon has precise manoeuvrability in strong cross-currents and is the most successful underwater vehicle of its class in the world.