PETRONAS is now in the midst of running a 5G Testbed Programme, as part of the Malaysian Government’s 5G deployment strategies.

The Programme, involving a cutting-edge demonstration facility set up at Institut Teknologi Petroleum PETRONAS (INSTEP) in Kuala Nerus, is being carried out with the support of the Malaysian Communications and Multimedia Commission (MCMC).

Minister of Communications and Multimedia, Dato’ Saifuddin Abdullah visited the Programme site recently, accompanied by EXCO members from the Terengganu State Government and a Celcom representative. Also present were MCMC Chairman Dr Fadhlullah Suhaimi Abdul Malek; PETRONAS Chief Technology Officer Dr Nasir Darman and INSTEP Chief Executive Officer Idris Ibrahim.

Dato’ Saifuddin told journalists that to date, there were 71 use cases (steps) for 5G technology being demonstrated under the 5G Demonstration Projects initiative, which are expected to contribute meaningfully towards the Government’s preparation to implement commercial 5G technology in the near future. He said:

“For individual usage, MCMC naturally wants to optimise 4G access for now, but for industries, there is definitely a need for 5G technology.”

Dato’ Saifuddin pointed out that for the oil and gas industry, only PETRONAS is participating in the demonstration project so far. Nevertheless, MCMC believes that more companies would be interested in using 5G technology.

Dr Nasir Darman said:

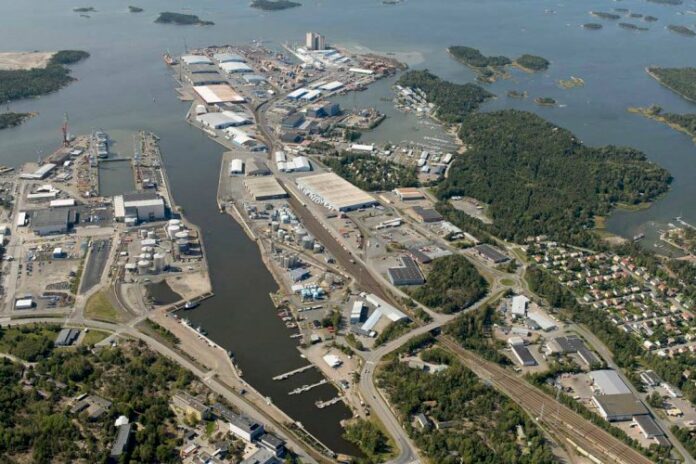

“The 5G technology is in line with PETRONAS’ aspiration towards automation and digital implementation, both within the Group as well as the oil and gas industry. PETRONAS aims to have fully remote operations in the near future. This fully remote operation will be conducted from an onshore control centre utilising 5G network, therefore significantly reducing hazard risks at offshore facilities while at the same time, supporting pace and sustainability.”

Dr Nasir highlighted that PETRONAS’ initiative in leading 5G tests for the industry’s 5G use cases is aimed at benefiting the ecosystem as a whole. He also urged the industry to deploy their own 5G use cases early to ensure that the needs of industry players are equitably addressed in 5G spectrum planning and policymaking.

The anticipated 5G adoption is an enabler to propel PETRONAS’ digital transformation agenda, leading to improved operational efficiency, safety enforcement, asset optimisation and increased productivity.