MAN Energy Solutions ME-GI engine sails through sea trials

NOAA awards $3.1 million to 21 small businesses to develop new technology for aquaculture

Terminal technology helps Crowley adapt to need for speed

A change in the terminal operating system (TOS) used by Crowley Maritime Corp has sped up truck turn times and allowed for better use of limited yard space within its three hubs in Florida and Puerto Rico. The shift is part of a decade-long operational change that’s paying dividends for the liner carrier and supply chain services provider.

An investment in off-the-shelf TOS software from Tideworks Technology helped to better align operations at Crowley’s key terminals from roll-on roll-off (ro-ro) vessels to lift-on lift-off (lo-lo).

The 10-year lag between Jacksonville-based Crowley making a shift in its physical operations model and the systems to support that shift underscores the need for third-party software to connect disparate supply chain activities and the role that terminal operators can play in aiding shippers, company executives told JOC.com.

Patrick Collins, Crowley’s vice president of terminal operations, told JOC.com, said:

“Our whole system was set up for a ro-ro model. Even though our vessels went to lo-lo, our terminals remained wheeled. We needed to move to a grounded terminal operation. And in order to go grounded, we needed a different system.”

Crowley had, until 2015, been using a homegrown TOS designed in the early 1980s that integrated with its homegrown container booking system.

Collins said:

“It was perfect for our operation, but we had outgrown it.”

That year, the company looked for an off-the-shelf solution instead of building something in-house again, and went with a TOS from Tideworks. The decision to go with off-the-shelf software at its hub terminals in Port Everglades, Jacksonville, and San Juan, Puerto Rico was driven in part by wanting a new perspective on its operations, but also to get more ongoing value from its investment in technology, Collins said.

Mike Porkert, Crowley’s director of terminal systems, said:

“Many of the processes and operations at any of our three Crowley terminals were maintained informally through post-it notes, tradition or just sticking with what worked before. Tideworks’ technology helped create structure and organization to our processes. Usually there’s a lot of apprehension from the business unit about a new system and it’s easy to want to customize things, but we really wanted to adopt the system.”

Crowley first implemented the TOS at Port Everglades in 2016, then expanded it to Jacksonville and San Juan in 2017. Use of the standardized lo-lo-oriented TOS has resulted in an increase in gate volume and turn time reduction at all three facilities, Collins said. In Jacksonville, average turn time in the terminal has been cut by 37 percent, around 14 minutes, since Tideworks was implemented. In San Juan, in-gate times fell from an average of 45 minutes to 12 minutes. Time spent at gate kiosks at the Isla Grande terminal in San Juan went from an average of seven minutes to less than one minute.

Using the Tideworks TOS has created a shift in mentality at Crowley on the importance of data at the terminal level, since downstream, outside-the-terminal processes rely on the quality of that data.

Porkert said:

“Beforehand, if there was a data quality issue, the idea was ‘it’s okay, just make a phone call to correct it. This has created a shift in thinking, because if you put bad data in the TOS, it affects outgate and cargo availability. There was resistance off the bat, but within a few days, you couldn’t pry the computer out of their hand, as opposed to the paper and clipboard they used to use.”

Rotterdam: First trial using mobile degassing installation successful

A initial trial using a new mobile degassing installation on the public quay of the Seinehaven in Rotterdam has been successful. This concerns a degassing that took place outside an establishment and that is unique in the Netherlands.

The Port of Rotterdam Authority has been working towards enabling degassing in the port of Rotterdam for years now. Within the Rotterdam region, the Province of South Holland, the Municipality of Rotterdam, the Rotterdam-Rijnmond Safety Region, DCMR and the business community have collaborated closely to this end.

The vessel Visioen (3235 tons, about 3300 m3) was empty of petrol and all 10 tanks were degassed in order to be able to take on the next cargo. Degassing started at 9:20 a.m and at 4 p.m. the vessel was below 10% LEL (lower explosion limit). The aim of the trial is to determine whether the installation is suitable for degassing inland vessels without the emissions exceeding the standards. The installation must also be safe. The experiment was also used to test the permit conditions.

The Rotterdam-Rijnmond Safety Region, the DCMR and the Port Authority were involved in the trial. The technology was provided by ENDEGS.

It is prohibited to degas a number of substances, including benzene and petrol, to the outside air in the port of Rotterdam. Degassing while sailing is also prohibited in most provinces. In the coming period, the Port Authority will be testing various installations together with the Safety Region and the DCMR. The next degassing will take place at the end of August/beginning of September.

Photo: Port of Rotterdam

USCG releases new ballast water management reporting form

The new reporting form replaces all previous versions and the National Ballast Information Clearinghouse (NBIC) will no longer accept older versions of the form.

Under the US National Invasive Species Act of 1996 all ships arriving in United States must complete and submit a ballast water information report to the National Ballast Information Clearinghouse (NBIC). The aim is to quantify the amounts and origins of ballast water discharged and to determine the degree to which such ballast has undergone treatment or open ocean exchange. Vessels exempted from submitting NBIC reports can be found in 33 CFR 151.2015.

NBIC is a joint programme of the United States Coast Guard (USCG) and the Smithsonian Environmental Research Center (SERC). The programme collects and analyzes data on the ballast water management practices of merchant ships operating in United States waters and has been receiving ballast water reporting forms from arriving vessels since 1 July 1999. During 2019, in excess of 97,000 reports were submitted to the NBIC.

There are two important changes introduced in the new ballast water management reporting form. These are:

- The yes/no question “Alternative BW management conducted, per instructions from COTP” has been removed.

- All vessels are now required to report the date of their last dry dock, information that is critical to the Coast Guard for determining a vessel’s compliance date with the implementation schedule for approved ballast water management methods as set out in 33 CFR 151.1512 & 151.2035.

The new Ballast Water Management Reporting Form (OMB number 1625-0069, expiration date: 31 July 2023) can be accessed through the NBIC website as a PDF form or through the Web Application Form. Users should be aware that the standard form can report the ballast water history of up to 20 tanks while the extended form can report up to 36 tanks. Any report related questions, can be sent to the NBIC at nbic@ballastreport.org.

Source: gard.no

Maersk Training and US college announce offshore wind training partnership

Bristol Community College’s National Offshore Wind Institute (NOWI) has entered a global partnership with one of the world’s largest and most trusted providers of offshore wind training, Maersk Training.

Laura L. Douglas, President, Bristol Community College, said:

“Bristol is proud to partner with globally recognized Maersk Training, whose expertise and experience will elevate the college’s leadership in training the workforce needed for the emerging offshore wind industry. This partnership will connect the college’s faculty and staff with the expertise of industry experts throughout Maersk Training’s expansive global network and will strengthen the development of employment opportunities for Bristol students in the offshore wind supply chain.”

The collaboration is the next step in securing Bristol’s National Offshore Wind Institute as the region’s leader in basic safety training and basic technical training programs certified by the Global Wind Organization (GWO).

Johan Uggla, CEO, Maersk Training, said:

“We are really excited about this partnership with Bristol Community College and the wind energy developments in Massachusetts on the East Coast of the United States. Having a local workforce that has a strong level of competencies, technical skills and safety, that drives operational and safety performance, is essential for the industry and the success of these projects. This is an important milestone that supports creating further job opportunities and being a strong provider for the local economy.”

Maersk Training is part of A.P. Moller – Maersk Group, a company that has been in the U.S. for many years focusing on shipping, ports and logistics. Alex Øbell Nielsen, Head of Business Development for Maersk Training, said that the partnership will tap into decades of offshore wind training experience. A strong benefit for students who attend the college and the local community.

Alex Øbell Nielsen said:

“For more than 40 years, Maersk Training has been delivering training to the offshore industries and helping our customers improve safety operational performance. Maersk Training will work closely with Bristol in developing new courses and participating in a close partnership supporting offshore wind in Massachusetts with the skills and competency to work in the industry. We look forward to this long-term partnership.”

NOWI’s basic safety training modules include the areas of first aid, manual handling, fire awareness, working at heights and sea survival, whereas the basic technical training courses focus on hydraulics, mechanical and electrical concepts regarding offshore wind. Maersk Training is at the forefront of offshore wind skills development. The partnership will establish the skills development training portion of NOWI and develop new GWO courses offered by Bristol Community College that are currently tailored to in-demand industry skills and knowledge.

The GWO is a non-profit organization, founded by leading turbine manufacturers and owner/operators, with the goal of creating a safer, more productive workplace. The GWO Basic Safety Training program (GWO-BST) was created as the safety standard for those working in the wind industry.

NOWI will span the knowledge spectrum with GWO-accredited skills development in partnership with Maersk Training on one side, while meeting the demand on the business / non-technical side through the Innovation & Entrepreneurship Center, which will stimulate new venture and job creation supporting economic development in Massachusetts and throughout New England.

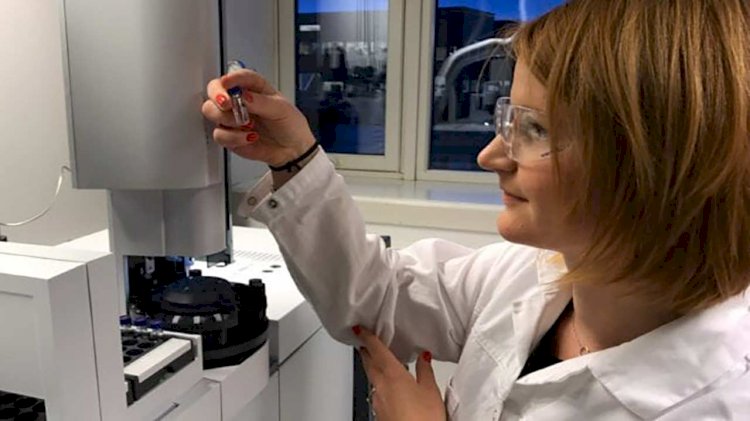

Study: A toxic cocktail in Norwegian waters – chemicals from car tires rubber

Crumb rubber granulate (CRG) produced from used car tires, also called end of life tires (ELTs) is commonly applied to synthetic turf pitches, including football fields, playgrounds, and walkways in Norway.

In addition to the rubber itself, tires also contain fillers, stabilizers, pigments, oils, resins and a range of other organic compounds and heavy metals. A new study found that CRG readily leached this cocktail of organic additives and metals into seawater.

This included high concentrations of benzothiazole and zinc, as well as detectable levels of PAHs and phenolic compounds. In a recent scientific publication, lead-author Claudia Halsband (Akvaplan-niva) explains:

“Previous studies have mainly investigated CRG leaching behavior in soil and freshwater. However, a lot of this rubber enters coastal marine environments in Norway, both from tire wear on roads and in snow removed from artificial turfs. We therefore wanted to investigate if CRG can contaminate seawater and if it is toxic to marine organisms”.

In a comprehensive laboratory study, Halsband exposed small planktonic crustaceans (copepods) to a wide range of rubber leachate concentrations diluted in seawater. Halsband says:

“The leachate was toxic at high concentrations, shown through high mortality of the copepods within a few days. Very low concentrations, in contrast, did not lead to mortality and seemed to be tolerated by the organisms, at least in the short term. The problem is that we currently do not know what concentrations of CRG and tire wear particles are present along the Norwegian coast, and what exposure scenarios are realistic in the marine environment.

We also have not yet looked at the long-term effects of low doses, which could induce sub-lethal effects that negatively affect marine populations in the longer term.”

The findings of the study were published as part of the Research Topic Biogeochemistry of Anthropogenic Particles in the journal Frontiers in Environmental Science with co-authors Lisbet Sørensen and Andy Booth from SINTEF Ocean and Dorte Herzke from NILU. The study was funded by the Fram Centre Flagship Hazardous Substances.

Photo: Akvaplan-niva

DNV GL verifies Portsmouth International Port’s infection risk protocols

The assessment of the port’s infection risk protocol assures passengers that robust infection risk control measures are in place. It covers passenger facing activities including the terminal building, security control, car search bay, shuttle buses, passenger boarding bridge and public gardens.

Andrew Williamson, passenger operations manager at Portsmouth International Port said:

“Our aim was to give passengers confidence that the new preventative measures we have put into place are of the highest standard, and to highlight the benefits of international travel by sea. This verification from DNV GL provides further reassurance about the efforts we are taking to keep them safe. The whole port has worked together to make sure we can carry operations with the highest level of care.”

The My Care™ methodology applies a hospital grade infection risk management approach. It brings together aspects of DNV GL’s healthcare standards, best practices in risk management, HSE and quality management systems and maturity safety rating standards.

Aileen Orr, Business Assurance’s UK Healthcare Lead in DNV GL, said:

“The port demonstrated that it has a well-considered approach to managing infection risk. Due attention has been given to the latest international and local guidance along with relevant industry bodies such as the British Ports Authority (BPA). This demonstrates the Port’s willingness to take the necessary steps to make their passengers’ journey as safe and comfortable as possible. Of particular note was the partnership working with the operators sailing from the port to ensure consistency in managing infection risk”.

Meyer Turku will permanently layoff 166 people

The First part of Meyer Turku’s YT negotiations have now come to a conclusion. Meyer Turku will permanently layoff 166 people.

The number at this point includes 86 blue collars and 80 white-collar workers. Due to the production schedules of the shipyard the negotiations concerning outfitting, design and HR functions will continue and will be finished during this year.

The corona crisis has changed landscape of cruise operation and shipbuilding drastically. In April Meyer Turku announced the objective to stretch out the order book reaching then to 2025 to secure work for years 2025 and 2026. At the same time, the Meyer Turku started negotiations to permanently layoff 450 people.

With the lay-offs, Meyer Turku will also start a transition program where everybody willing will get personal guidance, support and specialized training to ease the transition.

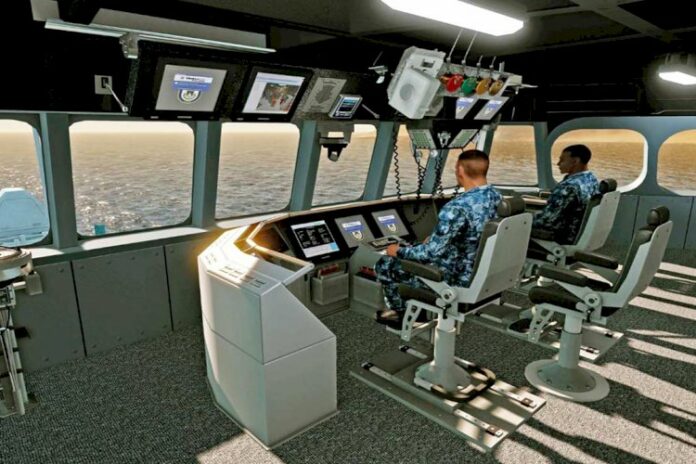

Alion awarded $896M navy integrated training environment contract

Alion Science and Technology announces today that it has been awarded an $896M task order under the Naval Sea Systems Command (NAVSEA) SeaPort-NxG multiple award contract for the development, integration, management, and support of the Navy Integrated Training Environment (NITE).

Steve Schorer, chairman and CEO of Alion, said:

“For more than 20 years, Alion has been dedicated to the Navy’s training missions supporting the Navy Continuous Training Environment (NCTE) and designing, developing and operating the Navy Enterprise Tactical Training Network (NETTN). We understand the critical role training has in continuing to ready the Navy for multi-domain and all domain warfare. Alion is committed to seamless integration, management and enhancement of the Navy’s training environment to ensure battle readiness. This most recent contract award highlights the tremendous momentum the company has towards providing the best innovative technical solutions to support our customer’s missions.”

The primary purpose of this effort is to provide an integrated program that will enable a continuous, multi-domain, Live, Virtual and Constructive (LVC) training platform across multiple physical locations throughout the Navy Training Enterprise. Alion will integrate the Navy Combined Tactical Training Range (CTTR) and the Southern California Offshore Range (SCORE) into the NCTE environment which includes more than 1,200 secure interconnected nodes throughout the United States and coalition nations. Additionally, Alion and its teammates will provide comprehensive Operations and Maintenance support to the Naval Training Enterprise throughout the duration of the contract activity.

Glenn Goodman, Operations Vice President of Alion, said:

“The Alion team’s combined expertise in modeling and simulation, engineering, and systems integration, along with its long history of event and experimentation support to the Navy, ensures the latest, most advanced technology and innovations are applied to the Navy’s LVC training environment. It is imperative that training environments and solutions excel at providing real world training for our warfighters, and Alion is dedicated to that mission.”

This contract has a 12-month base year, plus four one-year option periods.