Recent warming events in the Bering Sea have accelerated ecosystem changes that extend throughout the Arctic region, putting pressure on marine resources and the agencies tasked with monitoring the ecosystem and sustainably managing commercial, recreational, and subsistence fisheries and hunting.

The National Oceanic and Atmospheric Administration (NOAA)’s mission includes conservation and management of coastal and marine ecosystems and resources. The NOAA National Marine Fisheries Service (NMFS) is specifically responsible for the stewardship of living marine resources such as fisheries and marine mammals in US federal waters. The Alaska Fisheries Science Center (AFSC) carries out the NMFS mission in Alaska and the Arctic.

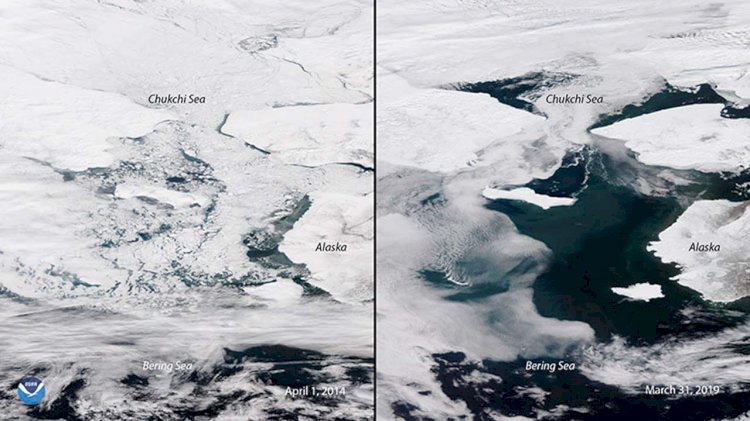

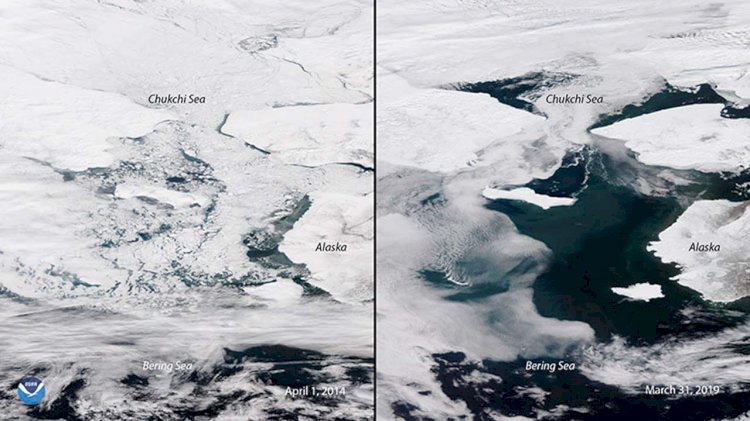

Arctic ice is in constant motion. Sea ice grows and shrinks with the seasons, moving with the winds and the currents. In “normal” years, by March, the ice extends south through the Bering Strait and well into the Bering Sea. Sea ice plays an important role in the Arctic ecosystem: It provides habitat for phytoplankton, birds, and marine mammals like seals and polar bears, and affects the migration routes of whales and seabirds. As sea ice forms, it leaves behind cold, briny water; when it melts, the water becomes less salty. The annual freeze/thaw cycle of sea ice is essential to the health and productivity of the ecosystem.

The Bering Sea “cold pool” is a large mass of frigid water that forms under the ice—temperatures in the cold pool are usually less than 2°C (36°F). The cold pool impacts the distribution of species, acting as a barrier between southern Bering Sea fishes and northern species.

A few years ago, scientists expected that sea temperatures in the Arctic would climb slowly and that, in the future, they’d need to address commercial fish species movement into the northern Bering Sea. But recent marine heatwaves accelerated the process significantly. In 2018, the cold pool was the smallest in the history of AFSC’s annual research survey, which spans 40 years. Alaska pollock and Pacific cod extended their habitat north, while key Arctic species, like Arctic cod, were scarce in the northern areas of the Bering Sea where they are commonly found.

Photo: Satellite images showing an adverse change in sea ice coverage in the Bering Sea on April 1, 2014 (left) and March 31, 2019 (right). Courtesy NOAA.

Robert Foy, the science and research director of the Alaska Fisheries Science Center, said:

“It doesn’t mean the environment will not return to more normal conditions. It might. We might not even be having this conversation a year from now. But this is a glimpse of what’s to come, and it’s expanded our entire mission.”

Climbing sea temperatures isn’t the only area of concern in the Arctic; scientists have noted changes in CO2 (causing ocean acidification) and oxygen levels. Ocean acidification refers to a reduction in the pH of ocean water and can affect the ability of crustaceans and other calcifying organisms to build their shells. With lower pH, will crabs adapt? Will they move? Or will they disappear? Any one of those scenarios could have a dramatic impact on the ecosystem. Foy says that research conducted at the Alaska Fisheries Science Center shows that pollock and cod are not likely to be as affected by CO2 directly, but their food source might—pollock and cod feed on crustaceans, zooplankton, and smaller fish.

Foy said:

“We need to collect a wide variety of environmental variables, not just temperature and fish biomass. That’s where we need to work together with other organizations.”

The eastern Bering Sea and Gulf of Alaska, an area twice the size of the eastern seaboard, takes months of ship time to zigzag back and forth during annual surveys. But environmental changes—less ice, warmer waters—mean that some fish have moved some 1,000 kilometers (600 miles) north.

Foy explained:

“Our mathematical models need to be able to predict the impacts of these environmental changes so that we can also predict the behavior of the fishermen who will follow the fish. You might not have thought the longline fleet would move 1,000 kilometers north, but they did. In order to effectively manage these fisheries, NMFS has to be there, too.”

Saildrone’s fleet of autonomous wind and solar-powered vehicles carry a payload of science-grade sensors to collect data above and below the sea surface—air, sea, and skin temperature, wind speed and direction, relative humidity, barometric pressure, photosynthetically active radiation, salinity, dissolved oxygen, chlorophyll, and wave height and period.

Foy says the idea is to use autonomous vehicles to augment ship-based surveys; the saildrones can cost-effectively ease the burden of data collection so that the humans onboard the ships can focus on collecting detailed biological and oceanographic data.

With several large-scale ship-based surveys in the region canceled due to the ongoing COVID-19 pandemic, scientists at AFSC undertook contingency planning to use saildrones to help fill the gap. The autonomous saildrone made it possible to conduct an acoustic survey and provide some helpful data in a year when it otherwise would not have been possible. The work this year builds off of a five-year collaboration between NOAA’s Pacific Marine Environmental Laboratory (PMEL), Saildrone, and AFSC.

Saildrone-based acoustic surveys are well-suited for the Bering Sea because pollock are the dominant fish species there, so scientists can be more confident the vehicle is actually measuring an abundance of pollock and not some other fish species.

Three saildrones were deployed in mid-May from San Francisco for the 2,000 nautical mile transit to the Bering Sea. Arctic missions usually begin from Dutch Harbor on Unalaska Island, but travel restrictions meant that the vehicles had to be deployed from Saildrone headquarters. After some 40 days at sea, the vehicles reached Unimak Pass and entered the Bering Sea to begin the survey.

Each vehicle took a third of the 600-nautical-mile-wide survey area between Alaska’s Aleutian Islands and the western edge of the US exclusive economic zone (EEZ). Based on previous year’s surveys, Foy says that while Pacific cod stocks had moved north, Alaska pollock had spread out. The area surveyed by the saildrones represents the footprint of the canceled acoustic-trawl survey.

The saildrones continued to collect other environmental data throughout the survey, some of which were made available to weather forecast centers worldwide via the World Meteorological Organization’s Global Telecommunication System (GTS).

All three vehicles have completed their transects and are headed back to San Francisco to deliver the raw data for processing.