In its efforts to become climate neutral, Port Esbjerg has formed a partnership with technology company Honeywell. The project is a global first. No other port anywhere has launched such an extensive climate project.

A shore power supply station complete with batteries, allowing ships to hook up and tap green electricity when docked at the port. Digitalisation of the shore power supply to measure the reduction of the carbon footprint. Digitalisation of the energy consumption of vehicles and mobile equipment at the port to measure the reduction of carbon emissions when converting from fossil fuels to electric power. These are just some of the ideas being discussed by a new technology partnership between Port Esbjerg and technology giant Honeywell.

Honeywell is a global leader in measuring and managing digital transformation for cities and airports working to become greener and smarter. The company also works to digitalise and manage energy systems in buildings, and now it will also assist in making the port of Esbjerg emissions free by developing a system for managing and monitoring resources, energy consumption and carbon emissions at the port.

Port Esbjerg CEO Dennis Jul Petersen, explains:

“We have an obligation to reduce our carbon footprint, and given our size, the many ships calling and the broad range of activities going on here in general, carbon emissions at the port are quite substantial, and we intend do something about it.”

However, there is no simple solution. It is a big and complex task. The shore power supply installed for ships calling at the port is a good example.

Jul Pedersen says:

“It’s easy to supply power to ferries that arrive and leave again at specific times on a daily basis. The rest of the traffic at the port is different, and that makes it difficult to implement a green transition which also makes business sense.”

To solve this challenge, Port Esbjerg has teamed up with Honeywell to develop a complete digitalised solution that will compile data on energy consumption at the port while also flagging up potential improvements. This solution is a global first for ports anywhere in the world.

Lana Sukhodolska, Head of Sales and Business Development at Honeywell, says:

“The solution we’ll be developing together with Port Esbjerg is absolutely unique in terms of its scope. Other ports may have energy efficiency solutions for their buildings, but no one has ever done what we’ll be doing at the port of Esbjerg. We’ll include everything from vessels, infrastructure and maybe also various companies operating at the port.”

In its initial phase, the project will map the energy consumption and carbon emissions of ships, buildings and port operations. Next, it will develop methods for additional electrification, digitalisation and management of energy consumption and emissions relative to port operations.

Sukhodolska explains:

“The people at Port Esbjerg know what they want, and in many ways, we see Port Esbjerg as a benchmark for other ports, especially in terms of sustainability. However, in order for this project to succeed, we need to establish what the company’s current position is. During this initial phase, we will map, monitor and manage current energy consumption and carbon emissions.”

Honeywell and Port Esbjerg are now collaborating on the development of the system which can provide a complete picture of carbon emissions at the port. Once in use, the system will enable Port Esbjerg to trace and manage all energy consumption remotely and in real time – it may even be able to do the same for energy generated by solar panels and battery-charging infrastructure to be installed in the future. This will also benefit the companies operating at the port, as they will be able to track their individual carbon footprints.

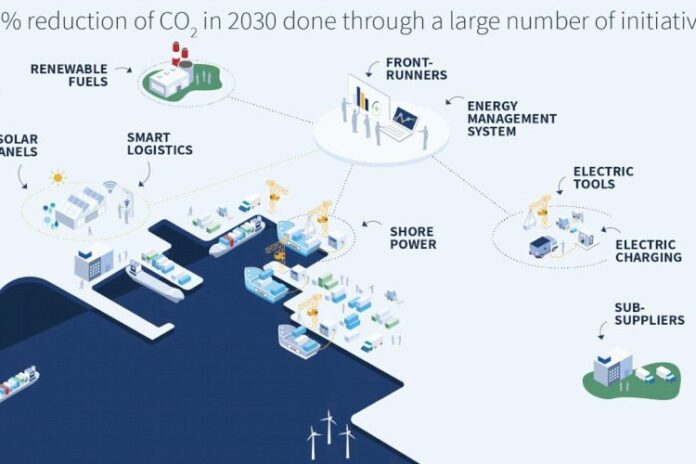

Port Esbjerg has prepared a carbon pledge with a target of a 70 per cent reduction of carbon emissions by 2030. The idea of the pledge is to voice the company’s support for businesses showing leadership and making the changes necessary to reduce the carbon footprint at the port of Esbjerg.

As part of the work to achieve their 2030 targets, Port Esbjerg and the oil and gas companies have prepared a road map, illustrating the actual progress of the port and the companies in meeting their climate commitment. For example, every company will need to look at the possibility of using power generated by green energy sources, such as wind turbines or solar panels. In addition, Port Esbjerg and the companies are working to establish smart lighting and smart heating. Plans are also to have shore power facilities providing access to green power for ships and for both Port Esbjerg and the companies operating at the port to step up investments in electric vehicles.

The system being developed in collaboration with Honeywell will make it easier for Port Esbjerg to reduce the carbon footprint at the port and achieve the 2030 target, but there will also be other positives from digitalisation.

Sukhodolska explains:

“The system will facilitate maintaining and optimising the consumption of resources at the port, because it’ll be easy to spot where improvements may be made. If something is not working as it should, it will be simple to rectify, and that will mean financial benefits for the port in general.”

Port Esbjerg will have the initial data from the system available in the autumn. Based on the new knowledge to be generated, the company will then have to decide on the next steps to reduce carbon emissions.

Jul Pedersen says:

“For us as a port, the new system will mean that not only can we lower our carbon footprint and we can do it faster, we’ll also be able to do it in a way that makes sound business sense. If it meant we’d incur higher costs, it would be to the detriment of our customers at the end of the day, and that wouldn’t be fair. This way, we’re making the port more attractive by facilitating the green transition while also staying open for business.”