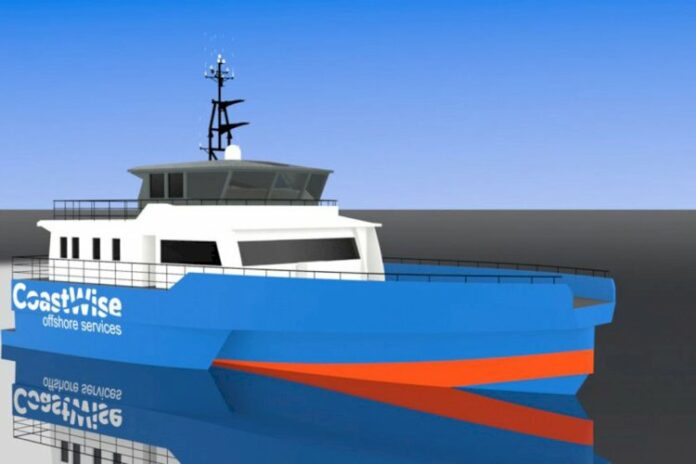

The signing took place at Next Generation Shipyards on Lauwersoog (the Netherlands). The contract involves a special new type of vessel which combines the stability of a catamaran with the speed and fuel efficiency of a monohull. The building of the vessel was at the initiative of Coastwise Offshore Services, the new shipping enterprise owned by Messrs Eelko Wijdieks, Douwe van den Berg and Onno Nienhuis. The project also gives a significant impulse to the province of Groningen.

A new, Lauwersoog-based shipping company which applies itself to the offshore wind industry, an innovative, homebuilt vessel, and an investment of € 5 million – the harvest of more than 20 months of enthusiasm, dedication and faith in a lasting future. And the festive climax: the signing of a contract between shipping company COS Master and the Groningen shipbuilder Next Generation Shipyards in Lauwersoog for the building of an offshore service vessel. Harlingen-based SeaZip Offshore Service will be responsible for the commercial management of the vessel.

Shipping entrepreneurs Messrs Eelko Wijdieks and Douwe van den Berg, who have operated in the dry cargo market for years, are extending their operations to the offshore energy market. Everything fell into place after they had contacted Mr Albert Keizer, the Managing Director of Next Generation Shipyards, and the Ondernemershuis Noord-Groningen.

Says Douwe van den Berg from Coastwise:

“For quite some time already, Albert Keizer intended to design a crew tender himself. Our plans complemented one another well. In close collaboration with marine architect Fred van Dorresteijn (VDD Design, Dordrecht), Next Generation Shipyards succeeded in translating our basic principles into an unparalleled vessel design. The design provides the stability of a traditional catamaran and the speed and fuel efficiency of a monohull, which implies ultimate comfort combined with the best possible performance. Absolutely the best of both worlds”.

This combination is reflected in the name under which the new type of vessel is put onto the market: 30 Pax Monomaran Crewtender- Endurance class NG2727. The vessel will be delivered to Coastwise December next year and sail under the name of COS Master. The aluminium vessel is over 27 metres long, provides ample and comfortable room for 30 passengers and can carry a load of 15 to 22 tons. It will be fitted with a deck crane. Its cruising speed is 27 knots. The design is innovative and sustainable, which means that Next Generation Shipyards presents a concept which appeals to the market and symbolises the role which the Groningen region wishes to play in the field of energy transition and renewable energy.

Once the vessels have been completed, Coastwise Offshore Services will outsource the commercial management of the Monomaran Crewtender to SeaZip Offshore Service in Harlingen. Over the past decade, SeaZip has built up a substantial network in the offshore wind, oil and gas industry, both in Northern Europe and elsewhere in the world.