Peel Ports and CLdN are celebrating the addition of a second ferry service from the Iberian peninsula to Liverpool. The new weekly service connecting Portugal to Liverpool, has been introduced following the success of the first pure RoRo service between Santander, Liverpool, and Dublin (IE) in June.

Whilst most new services take time to build market confidence, these new connections have already proved a huge success, further increasing frequency and capacity on CLdN’s Irish and UK services from continental Europe. They offer cargo owners and hauliers the chance to utilise longer maritime routes, switching to unaccompanied trailers to improve the overall productivity of the driver pool.

Liverpool is a key port for the Atlantic and Irish Sea trades and this new route between Iberia and Liverpool, will provide both Irish and US exporters alike, with a reliable, fast and direct route for their customers, including those in northern Britain. Market uncertainty, related to COVID and Brexit, has presented a number of ongoing issues within the supply chain, affecting long distance European haulage and driver availability. This new service will mitigate all these risks.

David Huck, Managing Director at Peel Ports, said:

“This is a really positive start in our efforts to open up new trade opportunities amidst current market conditions. Many supply chains have been looking for alternative solutions given the challenges of moving cargo within a COVID environment. These services not only address those concerns, but also the potential risks from a no-deal Brexit in the UK’s negotiations with the EU, which are predicted to present delays on the traditional cross-channel routes.

The Port of Liverpool is ideally positioned to allow CLdN to benefit from the UK’s extensive port network as a viable alternative. It also means CLdN can take advantage of hugely reduced waiting times, storage and efficient onward routes. The new offering has provided a vital solution to protect and preserve every link in the supply chain. Specifically, it is able to support the reduction of long European haulage legs to deliver a robust and reliable service in the face of COVID-19 restrictions”.

Sjors Bosvelt, Head of Sales, CLdN said:

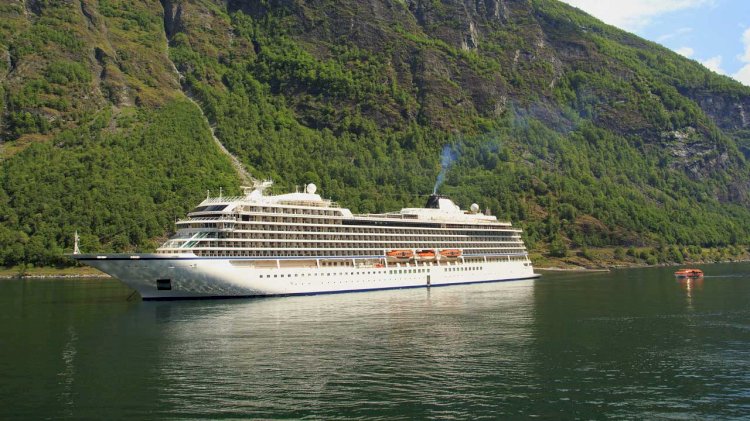

“Since launching the triangular route in June, plus Porto, Dublin, Liverpool sailings, we have continued to progressively expand our route network. The new Portuguese service, which commenced on 11th September with the arrival of Japanese built Kawasaki Class vessel, Clementine into Liverpool, will offer environmental benefits and be less prone to disruptions or interruptions as seen on the short straights, as well as increased coverage of direct shipment possibilities from Iberia to UK and Ireland.”