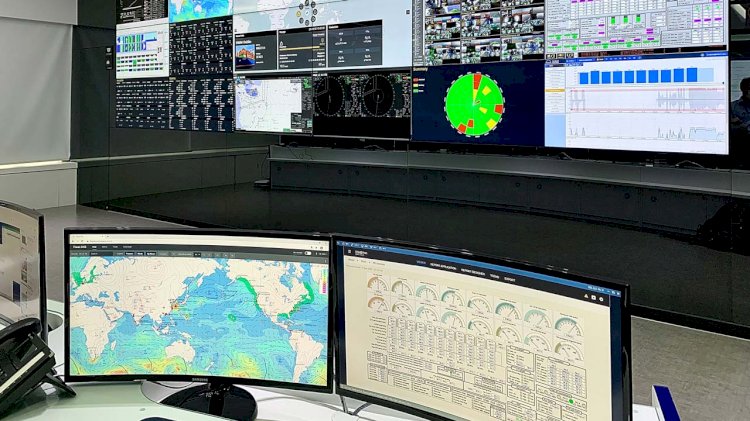

HMM unveiled its land-based ‘Fleet Control Centre’ located at the HMM R&D facilities in Busan, South Korea. This centre has been newly designed to effectively monitor and control the operation of HMM’s modern fleet including twelve 24,000 TEU and eight 16,000 TEU container vessels.

HMM has completed the delivery of its twelve 24,000 TEU containerships in September 2020, while eight 16,000 TEU vessels will be included in its fleet in the second quarter of 2021. All twenty ships feature the latest smart ship solutions.

The newly-launched Fleet Control Centre provides an integrated platform for vessel-to-shore data and increased connectivity. Its real-time monitoring system offers plenty of information with full visibility including vessel performance, locations, fuel consumption, ocean weather and cargo information etc. The vessels also can benefit from a remote control system which supports a wide range of vessel operations including inspection and repair works on the machinery on ships.

In addition, each vessel is encouraged to identify and react to an unexpected threat or obstacle both on board and around the ship by sharing information with the Fleet Control Centre in a timely manner.

HMM will continue to analyse the operational efficiency and explore the commercial viability of autonomous ships based on big data collected from the centre.

Jae-hoon Bae, President & CEO of HMM, said:

“Digital capabilities have become a key element in securing a competitive edge. We will accelerate efforts to enhance operational excellence and efficiency in our fleet management… We will also gradually apply the smart ship solutions not only to our newbuilds but also to the other ships already in operation.”