Electric boilers are a key component that make it possible to fully electrify Edvard Grieg, which in total will yield a reduction in CO2 emissions of around 200,000 tonnes per year.

Aker Solutions will be responsible for the engineering work, prefabrication as well as preparation of all underlying systems for the installation work offshore. Aker Solutions will also have overall responsibility for the system, and for ensuring a seamless transition from use of gas turbines to electric boilers.

Today, the power requirement is generated using a gas turbine equipped with heat recovery. Starting from 2022, Edvard Grieg will be connected to the area power from shore solution for the Utsira High. As from this point in time, the demand for heat will be filled by electric boilers.

A power from shore solution will be established for the installations in the southern part of the Utsira High in the North Sea in connection with Phase 2 of the Johan Sverdrup field development. A subsea cable will be laid from the Johan Sverdrup field center to Edvard Grieg.

Lundin Energy Norway’s Field Development Director, Charlotte Berge, says:

“We achieve several positive effects by getting electric power from shore, both in terms of operations and in the form of environmental benefits.

Shutting down the gas turbines contributes to an overall reduction of CO2 emissions of 200,000 tonnes per year. Operating costs will also be reduced since we will no longer need to operate our own power plant on the platform and we expect to see an improvement in operating efficiency.”

The Edvard Grieg platform was designed to receive electricity from shore from the very beginning of the construction phase in 2012. This was also a requirement set by the authorities. In 2014, the Norwegian Parliament (the Storting) decided that a solution would be developed to supply power from shore for Johan Sverdrup, and that the other platforms in the area would be connected to this solution in connection with Phase 2 of the Sverdrup development.

Charlotte Berge says:

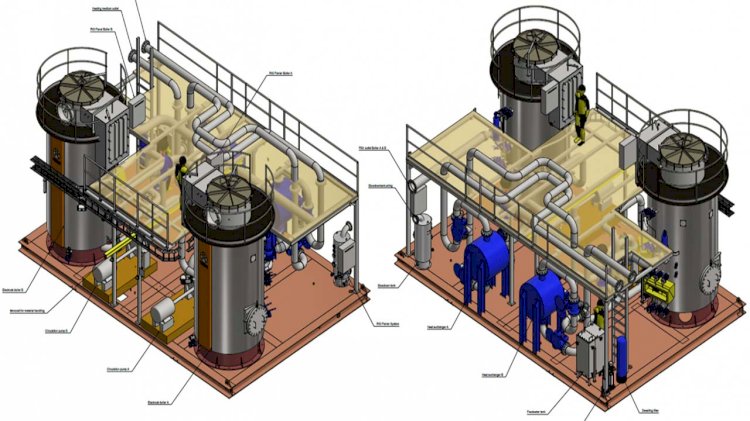

“Whilst receiving electricity for a platform via cable has been done before, adaptations to retrofit standard equipment from the onshore industry were needed to obtain the heat needed in the process plant. This will be an innovative solution in the offshore environment.”