Due to the Corona pandemic and the resulting travel restrictions, certification measurements were performed online.

Fu Min Chu, Vice President of Sales & Business Development at MTU China, said:

“China is our most important growth market and number one focus for our commercial marine business. This certification means we can now continue to offer our leading-edge technology to Chinese customers.”

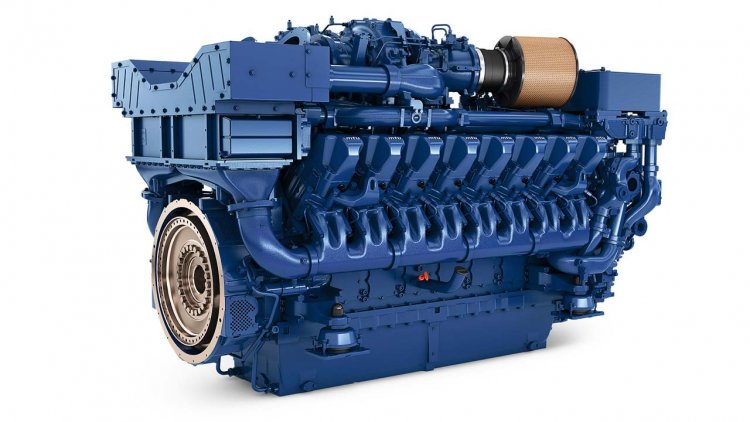

The China-1-certified MTU Series 2000 engines are available in 8, 12 and 16-cylinder configurations, and the Series 4000 engines in 8, 12, 16 and 20-cylinder designs – with power ratings between 720 and 4,300 kW. They are characterized by their low weight and compact size while offering high performance and reliability. The first engines with the new certification have already been sold, and some of them already dispatched. They are to be installed on a ferry in Shanghai and on boats operated by the Chinese police and customs.

To overcome the challenges posed by the Corona pandemic, the Rolls-Royce team and its partners came up with an innovative solution: The certification measurements were performed remotely for the first time. Cameras and an uninterrupted view of engine data monitors enabled the experts from Chinese classification society CCS and the Jinan Test Center to follow events on the Friedrichshafen test stand throughout.

Paul Röck, who headed the engineering activities of Rolls-Royce Power Systems in China at the time of the certification runs, said:

“A fully remote certification process has been unheard of in the mechanical engineering industry until now. So it’s all the more pleasing that this Sino-German project team has grown together so well and secured certification in this manner.”

MTU engines have been in service on Chinese ferries since the early 1990s. For example, two 16-cylinder MTU 4000 M23 engines power a catamaran plying the Pearl River Delta. Three fast ferries equipped with 12 and 16-cylinder Series 2000 M72 engines commute between Hong Kong and the Chinese city of Guangzhou.