For their first joint research project, they will conduct a proof of concept (PoC) on “Marindows”, a comprehensive digital platform for ships being developed by e5 Lab.

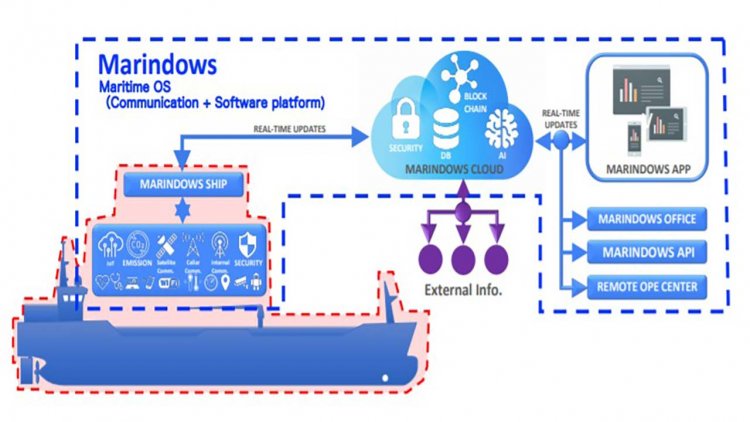

e5 Lab is developing a comprehensive digital platform for ships (Marindows) that consists of connection and applications necessary for the robotization of ships.

Marindows not only significantly improves the safety, productivity and efficiency of ships, but also enables them to evolve at the speed that software evolves, rather than at the speed of hardware as in the past. With OTA (Over the Air) updates, Marindows will continue to evolve to become safer, smarter, more efficient, and environmentally friendly.

The comments regarding this joint research are as follows.

Chief Technology Officer (CTO), e5 Lab, Mr. Yasumasa Suetsugu, said:

“e5 Lab will create new value and business in “environment (EV)” and “digital (Marindows)”, the growing industries of the 21st century. Working with the best partners domestically and overseas, Marindows will bring unprecedented innovation to the maritime industry.

By considering cyber security together with ClassNK, a cybersecurity expert in the maritime industry, we will expand the speed and scale of the digital revolution in the maritime industry that starts with Marindows. Digital and cyber security must be considered as a set, and I am deeply grateful for the opportunity to actively collaborate with ClassNK.”

Executive Vice President, Director of Innovation Development Division, ClassNK, Mr. Hirofumi Takano, said:

“We are very pleased to sign this joint research agreement with e5 Lab, who is engaged in cutting-edge digital initiatives, and be involved in such an advanced project. Cyber security measures must be widely implemented since the comprehensive digital platform forships needs to connect various devices and systems on board. Through this joint research, we would like to verify the best practices that the Society has jointly established with cooperating organizations, together with the e5 Lab experts, and use the knowledge obtained to establish standards for comprehensive digital platform for ships.”