The Digital Ship In-Service Support Project comes from the OSC’s Accelerated Ocean Solutions Program and brings together two Canadian marine industry leaders from Canada’s west and east coasts to develop and commercialize 3D digital twin capabilities that will help make Canada more globally competitive, drive export opportunities, and create jobs in the marine sector.

Led by British Columbia-based Seaspan Shipyards together with partner and Newfoundland and Labrador-based, Genoa Design International, the Digital Ship In-Service Support Project will receive $2 million from Canada’s Ocean Supercluster with the balance of funding coming from the project participants. This represents the first Ocean Supercluster project to be led out of Canada’s west coast. The relationship between Seaspan and Genoa was originally built under Canada’s National Shipbuilding Strategy (NSS) and continues to thrive today including a teaming partnership for Canada’s future Polar Icebreaker program. This type of outcome is exactly what the NSS was intended to create.

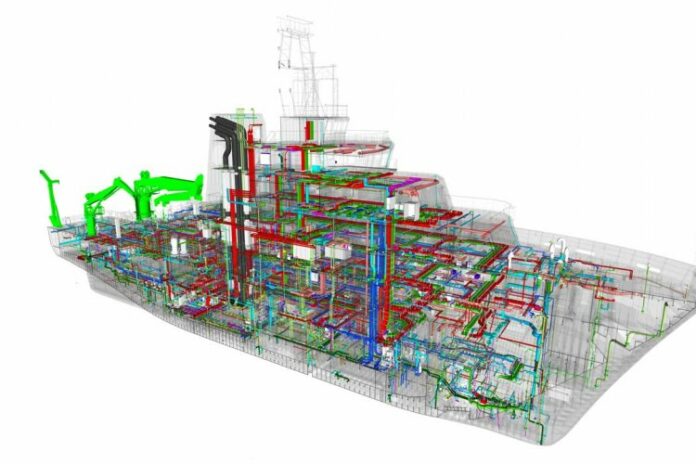

The project will develop new integrated capabilities for vessel management and maintenance through an advanced technology platform that will help vessel designers, builders, operators and maintainers more efficiently manage vessel lifecycle; reduce down-time for repair and maintenance by providing predictive information; improve vessel design and construction to reduce costs; and integrate multiple data sources by leveraging the language of visualization.

The Digital Ship In-Service Support Project makes this possible through its ability to provide:

- Data streams to manage vessel maintenance and predict maintenance issues;

- Dynamically-updated representations of vessels and their subsystems;

- Virtual reality to visually interrogate and interact with 3D digital twin data;

- A network of vessel sensors that report on the condition of the vessel and its subsystems; and

- Advanced artificial intelligence and machine learning algorithms.

Canada’s Ocean Supercluster is an industry-led transformative cluster focused on tackling the shared challenges across ocean sectors through a collaborative program designed to accelerate the development and commercialization of globally-relevant solutions, while also building a highly-capable, inclusive workforce. To encourage innovation and trigger new industry investment during these challenging times, the Ocean Supercluster supplemented its core programs with an additional project stream called Accelerated Ocean Solutions Program (AOSP). This enables the development of smaller projects on a shorter timeline that deliver tangible outcomes, while continuing to build resiliency in our ocean sector.

Navdeep Bains, Minister of Innovation, Science and Industry, said:

“The Ocean Supercluster is creating opportunities for Canadian businesses to come together from coast to coast, leading to new and innovative technologies that will solve real-life challenges faced by the ocean sector. The Digital Ship In-Service Project has the potential to distinguish Canada in a multi-billion-dollar global market while driving exports and new high-quality jobs.”

Kendra MacDonald, CEO, Canada’s Ocean Supercluster, said:

“This is a project that has been built on an exciting partnership between industry leading companies from Canada’s west and east coasts that will drive new export opportunities, increase our global competitiveness, and create jobs. Collaboration is at the very foundation of what Canada’s Ocean Supercluster is all about, and we can’t wait to see the game-changing outcomes that are delivered by Seaspan and Genoa Design through this exciting new project.”

Dave Belton, Director, Strategy and Business Development, Seaspan Shipyards, said:

“The marine industry is at an exciting time of innovation, where advanced digital technologies are enabling us to fundamentally transform how we build and maintain ships. With the support of Canada’s Ocean Supercluster and the Government of Canada, this Digital Ship In-Service project will bring new powerful and predictive capabilities for vessel management and maintenance and further Canada’s leadership in this important industry.”

Laurie Balan, Chief Technical Officer, Genoa Design International, said:

“This shared initiative has the power to transform the global shipbuilding industry, and with the support of the Canada’s Ocean Supercluster and the Government of Canada, it begins right here. As the foundation for the Digital Twin, the 3D model offers an incredible tool for collaboration, evaluation, and decision making. Together with long-time partner, Seaspan Shipyards, we look forward to maximizing its potential and building upon its proven success to advance this industry.”

Capt(N) Jacques Olivier, Director Digital Navy, Royal Canadian Navy, said:

“Digital Twins are one of the top focus areas of the Royal Canadian Navy’s Digital Strategy. Anchored by Artificial Intelligence and Machine Learning, Digital Twins incorporate real-time operating data from the physical platform and offer the possibility of optimizing the operation and maintenance of future naval systems. Canadian companies like Seaspan and Genoa have a key role to play in developing Digital Twin capabilities. This project is one great example of Canadian-led innovations being developed in alignment with one of the key priorities of the RCN.”