Valenciaport is making its debut in 2021 by joining the club of the 12 ports of the world that have the most investments committed to decarbonisation and emission reduction projects, the World Ports Climate Action Program (WPCAP), a working group that jointly promotes actions against climate change and that collaborates closely with the International Association of Ports and Harbours (IAPH).

The WPCAP was created with the main objective of reducing CO2 emissions and improving air quality. The President of the Port Authority of Valencia (PAV), Aurelio Martinez, explained:

“We have adhered to this programme in which the biggest ports participate and which are the mirror in which the rest of the world port system is looked at as their activity has a subsequent impact on the rest of the port scale. It is an action in which the 12 leading ports of the world are participating and which they have invited us to take part in as a recognition of our management in sustainability in recent years in order to launch a joint climate action programme”.

The members of the programme are chosen from a group of ports with a proven commitment to the environment and with full guarantees to be able to meet the requirements of the World Ports Climate Action Program.

It should be noted that last July, the IAPH awarded two projects in environmental matters that are being led by the Port Authority of Valencia. These programmes are “GREEN C PORTS” – which has also received an EnerTIC award – and “LOOP PORTS”. Both initiatives were awarded in the World Port Sustainability Awards for their initiatives to find innovative solutions to reduce traffic congestion, improve air quality, reduce noise levels, forecast crane productivity and measure emissions in real time in the ports.

The WPCAP is an initiative to boost and coordinate the efforts of ports with the improvement of the environment by encouraging cooperation between all the actors in the logistics chain. The Port of Valencia will be part of this select group alongside those of Antwerp, Barcelona, Gothenburg, Hamburg, Le Havre, Long Beach, Los Angeles, New York/New Jersey, Rotterdam, Vancouver and Yokohama.

The ports integrated in the WPCAP have thus created a programme of climate measures centred on five axes:

- Increasing the efficiency of logistics chains through the development and harmonisation of digital tools.

- To promote the common approach of public policies on the reduction of emissions within large geographical areas.

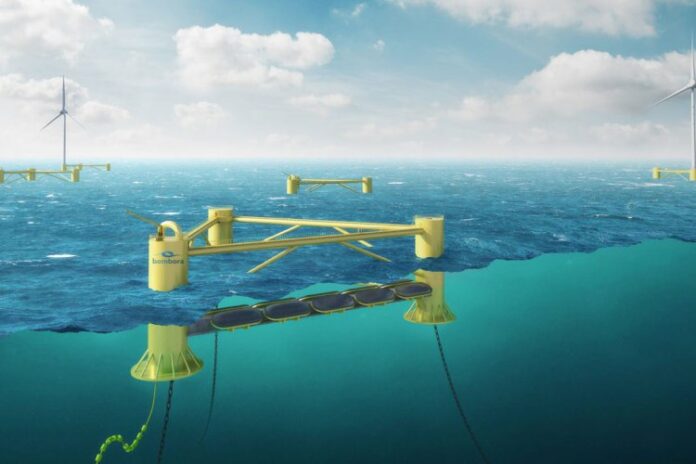

- Accelerate the development of renewable energies for ships or other “zero emission” alternatives in the docks.

- Accelerate the development of alternative fuels for ships, whose emissions are at least 50% lower than those generated by current fuels.

- Defend the “decarbonisation” of port terminals.

To carry out these lines, the ports involved in the WPCAP are working alongside the International Maritime Organisation (IMO) and representatives of the sector, governments, regulators and other agents to develop measures to advance the decarbonisation of the maritime sector.

PAV representatives are included in four of the five WPCAP working groups: Efficiency, Policy and Governance, Energy for Vessels, and Decarbonised Terminals. In this line, initiatives such as the Green Hydrogen with H2Ports roadmap should be highlighted, a pilot project for the area of mobility and maritime transport that is being carried out in the Port of Valencia to incorporate hydrogen in port logistics operations with the aim of reducing its environmental impact, and which will make Valenciaport the first port in Europe to incorporate hydrogen energy in its terminals by 2021.

In the area of sustainable infrastructures, the APV is developing projects such as the new North Terminal and the new Passenger Terminal, initiatives which, from the tendering phase, have the requirements that these installations must fulfil. These are focused on creating ecological, intelligent and accessible terminals that combine the generation of wealth and employment with respect for the environment.

Thus, the project presented by TIL for the new North Terminal of the Port of Valencia is designed to minimise CO2 emissions and energy consumption. Thus, it has measures to promote railway intermodality, it will be fully electrified for the supply of ships, 98% of the machinery will use electricity, and 100% of the energy will come from renewable sources. In addition, the automation of the equipment, the use of advanced traffic prediction systems, the design of the buildings with energy efficiency criteria, and the external lighting system with LED-type luminaires, will make it possible to minimise energy consumption.

In this line, the new Passenger Terminal project presented by Balèaria will have 100% of the energy coming from renewable sources, the recycling of waste recovered from the ships and the maritime station to produce biofuels, the electricity supply network for the ships at berth, the design of the roofs of the buildings for the installation of photovoltaic solar panels or the protection of the historical and cultural heritage of the buildings.

In addition, the Business Plan includes actions to promote green energy and reduce energy consumption within the framework of Valenciaport 2030, zero emissions. Thus, 3.2 million euros will be invested in energy efficiency programmes and consumption control systems, while 15 million euros are planned for wind power and 2.8 million for photovoltaic systems in the generation of alternative energies.