ABS, Nanyang Technological University (NTU), Singapore, and the Ammonia Safety and Training Institute (ASTI) are collaborating on a study of the potential of ammonia for Singapore, exploring supply, bunkering, and safety challenges with the marine fuel.

Titled Ammonia as a Marine Fuel in Singapore – Supply Chain, Bunker Safety, and Potential Issues, the joint study will look at safety protocols and possible gaps in the supply chain of ammonia as a marine fuel, specifically bunkering for marine vessels.

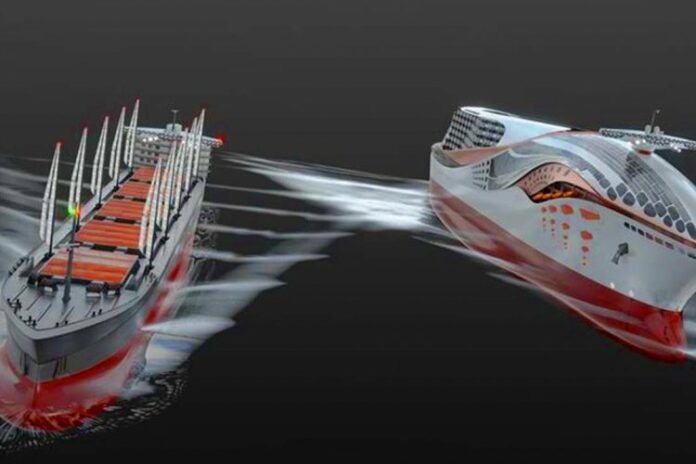

ExxonMobil, Hoegh LNG, MAN Energy Solutions Singapore, Jurong Port, PSA Singapore and ITOCHU Group with their partners, are initial project partners, contributing technical information about marine fuel handling, vessel to vessel transfer and bunkering in the Port of Singapore.

Panos Koutsourakis, ABS Director of Sustainability Strategy, said:

“Ammonia is a fuel with significant potential for marine applications and ABS is leading the way in understanding challenges in the safe design and operation of ammonia-fueled vessels. It is also clear that Singapore has the potential to play a critical role as a strategic downstream location to receive, store, consume or bunker ammonia. We are proud to be able to utilize our industry-leading experience with ammonia to contribute to understanding the opportunities and challenges presented by ammonia to the Port of Singapore.”

Professor Jasmine Lam Siu Lee, Director, Maritime Energy & Sustainable Development Centre of Excellence, NTU Singapore, said:

“This joint study is timely as it is aligned with NTU Singapore’s Maritime Energy & Sustainable Development (MESD) Centre of Excellence’s focus on alternative fuel research for the maritime industry, and ammonia is a key potential marine fuel. We look forward to working together with ABS and ASTI, in a collaboration supported by the Singapore Maritime Institute, to jointly deepen the understanding on various aspects of ammonia’s maritime applications. The research effort is in tune with Singapore’s long-term maritime decarbonization strategy, contributing to a more sustainable Maritime Singapore.”

Gary W. Smith, ASTI President and CEO, said:

“Ammonia is set to play an important role in helping decarbonize the maritime industry and ASTI is very pleased to be part of this study. We are committed to contribute as much experience and information as we can regarding ammonia safety to this important project.”

Brian Østergaard Sørensen – Vice President and Head of R&D, Two-Stroke Business – at MAN Energy Solutions, said:

“We view this study as closely aligned with our own strategy of cooperating with external partners to develop sustainable technologies and believe ammonia to be a very interesting candidate as a zero-carbon fuel. A suitable engine technology is, of course, key and MAN Energy Solutions already has a convincing track-record in developing engines running on alternative fuels. Indeed, we aim to deliver the first ammonia-fueled, two-stroke engine in 2024. We look forward to adding our expertise to this study to the benefit of Singapore, which is such a vital shipping hub.”